EMSNOW Innovation Update Q2 2021- Looking Like a Roller Coaster

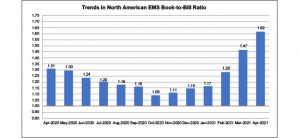

The 2020s are certainly earning the right to the label from last century: The Roaring 20s. As we watch Q2 unfold, it’s been a bumpy ride. One look at IPC’s North American EMS book-to-bill chart and you reach for the motion sickness bag.

“The North American EMS industry once again hit a new record this month with the book-to-bill ratio hitting another all-time high,” said Shawn DuBravac, IPC’s chief economist. “It is clear supply constraints and other disruptions are stymieing production while at the same time orders continue to be very strong. As a result, backlogs continue to build in the electronics supply chain.”

The good news, which we have been hearing on nearly every Up Close and Eric Miscoll Show (EMS) interview is that the pandemic did not completely devastate the industry by any means. Governments around the world realized the essential nature of electronics manufacturing and most companies we heard from were able to find a way to keep their employees safe — their highest priority — and also service their customers and book new business. It’s an amazing testament to the industry’s resilience and creativity.

Some challenges do lie ahead. For one thing, the vaccine is not being evenly distributed globally and Asia especially is experiencing some very disappointing and unexpected set backs in the battle against the disease. Supply chain disruptions from natural and human mishaps continue to plague the component industry, especially semiconductors. Demand is picking up dramatically. Bloomberg’s Global Purchasing Managers’ Index Tracker shows green nearly everywhere. In the U.S., the government stimulus spigot is not being shut off anytime soon. And the same electronics industry growth drivers that were revving up pre-pandemic — IoT, 5G, telematics, autonomous vehicles, and so forth — are champing at the bit. For companies that are well-positioned and used their pandemic downtime wisely, the second half of 2021 should be fun.

Here’s an update on some companies with high marks for innovation

The Specialists at TTI, Inc. stock not only a broad and deep inventory of connectors, caps, resistors, electromechanical components and more; they also deliver specialized knowledge of component markets and new technologies. They have partnered with premier suppliers to produce a series of webinars on products and technologies that can overcome design challenges. To see the full slate of webinars, register for upcoming presentations or watch on-demand videos of past events, visit the TTI Webinars homepage.

TTI also delivers the latest market news and information, published weekly on the MarketEYE Resource Center. For almost three decades MarketEYE has been the electronics industry’s resource for lead time trends, raw materials pricing and other supply chain news and insights. Follow TTI’s LinkedIn news feed for the latest headlines.

TTI also delivers the latest market news and information, published weekly on the MarketEYE Resource Center. For almost three decades MarketEYE has been the electronics industry’s resource for lead time trends, raw materials pricing and other supply chain news and insights. Follow TTI’s LinkedIn news feed for the latest headlines.

Innovation in Low-temp Solder

Indium’s Durafuse™ LT is a patent pending low-temperature alloy system designed to provide high-reliability in low-temperature applications that require a reflow temperature below 210°C.

Durafuse™ LT provides improved drop shock resilience, outclassing bismuth-tin (BiSn) or bismuth-tin-silver (BiSnAg) alloys, and performing better than SAC305 with optimum process setup. Durafuse™ LT is made up of a low-melting indium-containing alloy and a higher-melting SAC alloy. The SnInAg alloy initiates joint fusion while the SAC alloy provides enhanced strength and durability. Durafuse™ LT is ideal for high-reliability applications, which utilize thermally sensitive components or boards and/or have a requirement for step soldering.

Durafuse™ LT provides improved drop shock resilience, outclassing bismuth-tin (BiSn) or bismuth-tin-silver (BiSnAg) alloys, and performing better than SAC305 with optimum process setup. Durafuse™ LT is made up of a low-melting indium-containing alloy and a higher-melting SAC alloy. The SnInAg alloy initiates joint fusion while the SAC alloy provides enhanced strength and durability. Durafuse™ LT is ideal for high-reliability applications, which utilize thermally sensitive components or boards and/or have a requirement for step soldering.

Features & Benefits

- Drop Shock – Performance is more than two orders of magnitude better than Bi-containing low-temperature materials

- Drop Shock – Performance is equal or better than SAC305 with proper process optimization

- Ideal for step soldering and low temperature requir

Play it Safe with Comprehensive Testing

The immediate challenge facing so many manufacturers, particularly those in automotive, are the component shortages. Finding long lead-time, hard-to-find, and obsolete components from the open market for hi-rel industries like automotive, medical, defense, and aerospace, is particularly challenging as authentic parts could be old or stored improperly, leading to functional and reliability concerns. The risk of commercial grade components being re-marked as industrial, automotive or military parts has never been more real, and can be verified with full tri-temp testing.

In addition, today’s technologies are developing at breakneck speed. No sooner is a product on the market than it is updated. Electronic components are therefore becoming obsolete faster than ever before. The life cycle of a product often far exceeds that of its major components. The average lifecycle of a new integrated circuit is under two years today!

In addition, today’s technologies are developing at breakneck speed. No sooner is a product on the market than it is updated. Electronic components are therefore becoming obsolete faster than ever before. The life cycle of a product often far exceeds that of its major components. The average lifecycle of a new integrated circuit is under two years today!

Obsolete parts are not easy to source. They often tend to end up in the gray markets, enhancing the risk of buying a risky secondhand or counterfeit component. The result is in the best case a large financial loss due to product failures. In the worst case, counterfeits can endanger the safety of your customers.

White Horse Labs’ solution is comprehensive testing.

White Horse Laboratories was founded in 2004 to directly combat the growing global proliferation of substandard and counterfeit electronics components. We established testing, inspection, packaging, and logistics services where no company like this previously existed, at the primary source of supply, to foreign and domestic distributors alike. Since then, we have set the standard for transparency, clarity, and customer service.

Solutions for a circular economy at GreenChips

With a chip shortage it is pivotal to find alternative sources for the parts you need. GreenChips might have some hidden treasures in stock. They specialize in excess stock management, meaning they take surplus goods of different partners and offer them on their sales platform. With partners like GE Healthcare, Continental and Tridonic they have a steady stream of excess parts.

![]() It is worth your while to look if they have the part you cannot find anywhere else. And even if you buy too much or have excess stock yourself you can always give it back to GreenChips. They use an advanced AI named M.A.R.C (market analyzer & research calculator) to evaluate the best price and keep an overview of the entire market to ensure every part gets reintroduced into the economy. This way they strive to make sure resources do not end up gathering dust in warehouses and instead get used in production. Especially now an economic use of all computer chips with as few waste as possible is important.

It is worth your while to look if they have the part you cannot find anywhere else. And even if you buy too much or have excess stock yourself you can always give it back to GreenChips. They use an advanced AI named M.A.R.C (market analyzer & research calculator) to evaluate the best price and keep an overview of the entire market to ensure every part gets reintroduced into the economy. This way they strive to make sure resources do not end up gathering dust in warehouses and instead get used in production. Especially now an economic use of all computer chips with as few waste as possible is important.

Another important aspect of their mission for a more sustainable industry are the investments in environmental projects. So, whether you are looking for a place to buy or sell, go and visit GreenChips because your contribution also helps the environment.

Award-winning Optical Inspection

Koh Young, the industry leader in True3D™ measurement-based inspection solutions, humbly accepted its first 2021 Service Excellence Award on 06 April 2021 during a CIRCUITS ASSEMBLY virtual awards ceremony. The program, now in its 29th year, is still an industry bellwether. It recognizes those companies dedicated to excelling in the crucial area of customer service. “For years, I have praised our support team. I have always known they are head and shoulders above the others, and now I have objective proof,” commented Mr. Danny Han, Support Desk Manager and founding member of Koh Young America. “I always see our SPI, AOI, and software winning awards for their ability to save manufacturers time and money, but what about the people? I thought it was about time the customer service and support engineers at Koh Young America received the same recognition. I am thrilled that we finally participated in this prestigious competition. It’s our first entry and our first win – it doesn’t get much better,” cheered Mr. Han.

Koh Young, the industry leader in True3D™ measurement-based inspection solutions, humbly accepted its first 2021 Service Excellence Award on 06 April 2021 during a CIRCUITS ASSEMBLY virtual awards ceremony. The program, now in its 29th year, is still an industry bellwether. It recognizes those companies dedicated to excelling in the crucial area of customer service. “For years, I have praised our support team. I have always known they are head and shoulders above the others, and now I have objective proof,” commented Mr. Danny Han, Support Desk Manager and founding member of Koh Young America. “I always see our SPI, AOI, and software winning awards for their ability to save manufacturers time and money, but what about the people? I thought it was about time the customer service and support engineers at Koh Young America received the same recognition. I am thrilled that we finally participated in this prestigious competition. It’s our first entry and our first win – it doesn’t get much better,” cheered Mr. Han.

Manufacturers decide the Service Excellence award winners, so this award is incredibly special to Koh Young America. “Who better to judge our abilities than customers,” said Enrique Hernandez, Koh Young America Service Manager for Mexico. “Our customers push us improve and reach the zenith of customer service success. This feedback helps us improve operations and deliver new ways to support our customers,” concluded Mr. Hernandez.

CIRCUITS ASSEMBLY also announced the winners of its 2021 Service Excellence Awards for electronics manufacturing services (EMS) providers. Koh Young celebrates each of the winners for their focus on achieving excellence. To help them reach their quality goals and satisfy their customers, over half of the award-winning EMS providers have integrated True 3D™ solder paste inspection (SPI) and automated optical inspection (AOI) solutions from Koh Young. The overall EMS winners were Kimball Electronics (sales over $500 million) and XLR8 Services (sales under $20 million). Qualitel tied for top honors in the sales of $20 million to $100 million category. The EMS companies with the highest scores in each of five individual service categories also received awards. In the small-company category, Silicon Forest Electronics won in all five categories. For firms with revenue between $101 million and $500 million, Mack Technologies won in each of the individual categories. For EMS companies with revenue over $500 million, Creation Technologies took home all five awards. Our congratulations to these Koh Young customers.

AOI for Placement Defects

The SEHO PowerVision stands for fast, automated optical inspection, and it is particularly designed for THT processes. The system can be configured depending on the manufacturing requirements: For component placement inspection in front of a wave or a selective soldering machine, or for solder joint inspection after wave or selective soldering processes, or as a combination of both inspection tasks, integrated into the same module to save space.

The system reliably detects typical placement defects such as presence of components or polarity, and soldering defects like incomplete solder joints, solder bridges or solder balls, for instance. Additionally, the system is capable of reading and processing product IDs.

The system reliably detects typical placement defects such as presence of components or polarity, and soldering defects like incomplete solder joints, solder bridges or solder balls, for instance. Additionally, the system is capable of reading and processing product IDs.

The stand-alone variant of the SEHO PowerVision can be flexibly integrated into each fully automated production line. Moreover, the system can be directly integrated in many of SEHO’s selective soldering systems, thus providing additional benefits, particularly in terms of floor space and board handling costs.

Generation of test plans is performed easily and comfortably at any PC using an offline teach program. Basic data can be taken from gerber data, DXF files or from any digital image file (camera or scan). A simple wizard leads the operator through the programming procedure. Moreover, the comprehensive and individually expandable component library includes component-specific test elements, as well as an automatic inspection search to simplify programming.

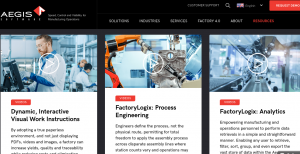

Don’t Just Rebound, Move Your Factory Forward

The Aegis team has spent considerable energy during lockdown developing new webinars, videos and white papers to enable the industry to adapt digital Industry 4.0 solutions. “The multitude of risks and challenges facing manufacturers today is accelerating the need to adapt process innovation, embrace technology, and digitalize,” they explain. “The imperative is for manufacturers to become more resilient, agile, productive, and profitable in a post-COVID-19 world. This challenge requires many to shift their mindset around digital transformation strategies. Although the transformative benefits of Industry 4.0 are crucial for a manufacturer’s survival and growth, not many have taken a concerted effort to be better prepared for the future. The time has never been better than now to re-imagine and reshape your digital manufacturing infrastructure to build more connected, collaborative, resilient, and highly integrated operations.”

These valuable resources are available on-demand.

Another company investing in training and education is ZESTRON. They have assembled an impressive array of online resources for pandemic lock-down when you’ve binged all that Netflix has to offer. The next live event is later this month:

Surface Cleanliness: How Clean is Clean? – June 22nd

Often impurities left on a board’s surface or underneath components may lead to field failures. Join the experts at ZESTRON Academy for an in-depth review of the standardized and non-standardized test methods available to properly assess the cleanliness of assemblies after the cleaning process. Attend this special webinar and discover the answer to a question we are so often asked – “How clean is clean?”.

Innovation in Labeling

IDENTCO is a leader in electronics identification, offering extreme durability, solvent and chemical resistance, anti-static properties, thermal transfer printing, automated SMT label application, and custom-designed solutions for applications that range from PC Board assembly to auto-applied solder masks to finished product labeling.

“We offer a robust range of off-the-shelf labeling and solder masking solutions for the electronics industry, as well as being fully equipped to take on the challenges of custom products” explained Brian Connolly, VP of Global Marketing at IDENTCO. ”Our miniature polyimide SMT labels and ultra-slim label feeders have caught the attention of SMT engineers worldwide. We welcome the challenge each new project presents, and believe the best customers are those who push us to explore uncharted territory.”

“We offer a robust range of off-the-shelf labeling and solder masking solutions for the electronics industry, as well as being fully equipped to take on the challenges of custom products” explained Brian Connolly, VP of Global Marketing at IDENTCO. ”Our miniature polyimide SMT labels and ultra-slim label feeders have caught the attention of SMT engineers worldwide. We welcome the challenge each new project presents, and believe the best customers are those who push us to explore uncharted territory.”

Innovation in EMS

Finally we’d like to spotlight three innovative EMS companies that have come onto our radar recently. The first is Pruefrex, a European EMS focused on control intelligence in combustion and electrical engines. Their innovations help protect the environment and contribute to better living comfort worldwide. “We are a driving force in the industry, supporting international industry leaders with our development and manufacturing expertise to help our partners and customers make the best products available in this highly competitive market” they say.

Finally we’d like to spotlight three innovative EMS companies that have come onto our radar recently. The first is Pruefrex, a European EMS focused on control intelligence in combustion and electrical engines. Their innovations help protect the environment and contribute to better living comfort worldwide. “We are a driving force in the industry, supporting international industry leaders with our development and manufacturing expertise to help our partners and customers make the best products available in this highly competitive market” they say.

The second company is headquartered in Asia.

ICAPE Group has been manufacturing Printed Circuit Boards and Customized Technical Parts in China since 1999. Now with a presence in more than 70 countries, +2000 customers trust the quality services and offers of the group. Each month, ICAPE Group delivers 22 million PCBs and 5 million Technical Parts. In 2019, ICAPE Group achieved a revenue of EUR 125M and aims for a growth in 2020.

With its teams of 450 people worldwide and 75 strategic partners in Asia, 25 in Printed Circuit Boards and 50 in Technical Parts, ICAPE Group brings some of the industry’s best supply solutions. The Services Office, located in China, is staffed by 230 highly qualified employees.

With its teams of 450 people worldwide and 75 strategic partners in Asia, 25 in Printed Circuit Boards and 50 in Technical Parts, ICAPE Group brings some of the industry’s best supply solutions. The Services Office, located in China, is staffed by 230 highly qualified employees.

“Our global sales organization allows us to be closer to the production plants and to satisfy your needs in Printed Circuit Boards and Technical Parts, with the best quality/ price/service ratios, while respecting the ethical charter established by the group on all its partners,” they explained. “Our main mission is to guarantee a quality service throughout the entire process: from quotation to delivery to any customer anywhere around the world.”

ICAPE Group is focused on developing its online presence and continues to better serve its customers. If you want to buy Printed Circuit Boards online, connect to www.icape-shop.com . You can order Customized Technical Parts online at www.cipem-shop.com.

ICAPE Group marks another milestone by joining forces with DIVSYS International, based in Indianapolis, USA. DIVSYS brings a US-based technical expertise in PCB and PCBA, coupled with a quality assurance laboratory and rapid prototyping assembly to a world-class PCB sales organization, ICAPE Group.

Here’s information about another innovative EMS based in Singapore, PCI.

Here’s information about another innovative EMS based in Singapore, PCI.

Founded in 1971, PCI is a leading specialist in electronics manufacturing services (EMS) headquartered in Singapore. It focuses on a comprehensive approach to manufacturing, operating as an extended resource of its global OEM customers who are leaders in their respective industries. Over the last 50 years, PCI has grown its team and established a strong reputation for depth of design and engineering capabilities, fast time-to-market, unparalleled quality and customer satisfaction, a well-integrated supply base, and well-executed capabilities. By offering comprehensive services that address the entire product lifecycle, including product design, manufacturing, testing, qualification, and supply chain management, PCI is a highly adaptable and responsive partner to its customers.

EMSNOW is committed to bringing readers the latest information about innovation in electronics manufacturing. Watch for our Innovation Update each quarter.

We will continue to bring you video interviews, features, news and analysis in the ‘Roaring 2020s’ and beyond.