Why Vertical Integration Adds Value

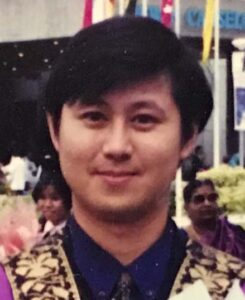

By CH Wong, COO of Flexi Versa Group

Some see vertical integration as having box-build in the same company as PCBA (printed Circuit Board Assembly), but there’s so much more to it than that. And there are so many more reasons to use a vertically integrated manufacturing partner.

But before we get into the value integration can bring, let’s explore why vertical integration works and why it is a strategic initiative for both manufacturers like Flexi Versa Group, and for the brands we work with.

CH Wong

Selecting which processes to integrate into a manufacturing offering demands strategic thought and an understanding of the industry, the processes, the investment required and the value it adds to every stakeholder. There are some obvious examples. We would never integrate semiconductor manufacturing into our offering. It is too niche, too specialized, it requires huge financial and time investment and a solid infrastructure and supply chain already exists. We would, and have, integrated plastic molding into our offering. This is a process we have experience and expertise in, can scale to suit our customer needs, and see a clear add value for the brands that we serve.

Other services we have vertically integrated include design, in-circuit and functional test, component sourcing (with specific expertise in EMI/RFI/ESD shielding seals and gaskets for mission critical applications that require both environmental and electromagnetic interference, electrostatic discharge and radio frequency shielding), woodworking (we’ll come back to that), plastic injection, elastomer solutions, final assembly and configure- and build-to-order capabilities. All these have been added strategically with an understanding of demand and out of deference to the voice of our customers.

Why integrate woodworking, I hear you ask. Simple, we have several customers in the audio market that really understand that wood delivers something unique and valuable in their product offering. An extensive woodworking setup includes advanced machines for laminating, edge-banding and more, and we have deployed state-of-the-art cyclone exhaust systems, keeping sawdust emission to the minimum.

Integrated With Our Customers

We have used three simple criteria to select the processes we vertically integrate.

- Is what our current customers, and future customers for that matter, want or need for us to be a good partner to them?

- Can we do it exceptionally well and deliver value as a result?

- Does the integration result in better value, greater efficiency and an overall improvement in performance?

Value From Vertical Integration Comes in Many Ways

The obvious reason to integrate is to provide a more seamless experience for the customer from the start to end of their product life cycle. Moving product from one outsourced manufacturer to another introduces friction and that friction comes at a cost, perhaps financial, perhaps quality or even reliability.

Let’s start with cost. Having our own in house processes, like plastics or woodworking means we don’t have to find sources for those processes on the open market and nor do our customers. That means there is only one margin, and we don’t have to add administration costs to select, audit and manage outside resources. By investing in the equipment we need to support our customers we naturally become the most economic source. And of course there are cost savings in shipping from one vendor to the next.

A lot has been talked about recently with respect to supply chain security. It stands to reason that the more complex a supply chain, the greater the risk of disruption. A more integrated manufacturing model is by nature a more integrated and compact supply chain, with less links to break. Add to this that control and IP remains with a single trusted source and it is easy to see that this is a more robust, yet agile solution.

Having a single source for multiple manufacturing, and even design and fulfillment disciplines, is bound to improve the quality and reliability of the product. Assuming the vertically integrated vendor has the right skills, equipment, processes and equipment.

Just as an example of how well this multi-disciplined vertical integration works, recent disruptions have driven rapid design changes in customer products. Because we have design in-house we’ve been able to redesign PCBs (Printed Circuit Boards) and housings to mitigate the disruption of parts shortages, all safe in the knowledge that our production process can adapt where needed.

All in all, vertical integration has delivered closer partnerships with our customers and better performance for them, their products and for us as a supplier.

For more information on our capabilities visit https://www.flexiversa.com/capabilities