Why a Cloud-based DFM Solution Is Critical In Today’s Global Economy

By Yossy Pinhas, Siemens Digital Industries Software

The COVID-19 pandemic has been a reality check for organizations of all sizes globally. Because of these uncertain times, more organizations, especially electronic manufacturers, are moving toward cloud-based solutions and digital transformation. The pandemic affected businesses and economies, forcing organizations to develop new approaches for employees and customers, requiring a remote workforce, flexible supply chains, and technology adoption for business transactions, communications, and customer support. With the pressure of added health and safety precautions in response to the global pandemic, cloud-based technology is expected to increase, with software as a service (SaaS) as one of the fastest-growing segments in the IT industry.

According to leading research company Gartner, cloud services are predicted at $396 billion in 2021, with a 21.7% annual growth rate to $482 billion in 2022. Brandon Medford, Gartner senior principal analyst, stated, “Organizations are advancing their timelines on digital business initiatives and moving rapidly to the cloud in an effort to modernize environments, improve system reliability, support hybrid work models and address other new realities compelled by the pandemic.”

SaaS subscription models that are centrally accessed on a remote cloud-based network are being developed for many organizations, providing business flexibility and affordability. For the electronics manufacturing sector, cloud-based solutions can streamline processes and improve workflows that can result in better product quality and delivery.

Electronics Design to Manufacturing Handoff Challenges Today

Today, one of the biggest challenges in the design to manufacturing process is the lack of manufacturing knowledge and data while still in the design phase. There is no communication between designers and manufacturers, so handoff to manufacturing is typically managed by the procurement department. Often, the manufacturing engineering departments face critical DFM violations like spacing and soldering issues that will impact the manufacturing yield. Challenges include:

- Insufficient spacing between components may not allow SMT machines nor technicians to properly place the components on the boards, impacting soldering, and technician access to connectors, switches and other types of interfaces for testing, debugging or design reworking.

- Various functional reasons (thermal or signal integrity) require proper spacing between components.

- Picking the wrong package size to meet requirements: fan-out, via type, layer stack-up, trace length, electrical characteristics, pad access and testability.

These are just a partial list of issues that must be validated before the design is handed-off to manufacturing. These issues require the designer to re-design and validate that there are no issues for manufacturability and quality of the designed PCB.

While the procurement aspects of PCB fabrication are important, what’s more critical is if the PCB design can be performed by the fabricator. With no direct communication between the designer and fabricator during the design stage, the designer may discover that the design does not comply with the manufacturer’s capabilities much later in the process, or a fabricator could realize that they are unable to fabricate a design. Designers and manufacturers have indicated that this is the main source for project delays, loss of business, low closing rate and low manufacturing capacity. Using cloud-based digital solutions can remedy this disconnect between the design and manufacturing processes.

Benefits of a Cloud-based DFM Solution

Organizations may question the need to move to the cloud, but with the growing trend of digital transformation and Software as a Service (SaaS) solutions, the benefits of adopting a cloud-based design for manufacturing (DFM) solution today makes sense.

- IT cost savings: A cloud-based SaaS platform can give eminent return on investment for several reasons. It removes the upfront expense of procuring hardware equipment, skilled IT resources, and on-going costs such as support and maintenance. Rather than spending a lot of cash on equipment, SaaS applications can be easily downloaded, maintained, and updated.

- A better option for smaller businesses: For small to medium businesses (SMB), a SaaS subscription model provides access to powerful technology and software that may have been generally unattainable via traditional software purchase strategies. A pay-per-use model helps organizations to buy just the software tools they need, versus buying for an entire tool suite with unnecessary products and services via traditional methods. The membership/subscription-based strategy can offer more flexibility for usage.

- Immediate access to tools and data to allow fast track to production: For most of the cloud-based SaaS applications, installation is as simple as having internet access and signing in. A cloud-based DFM solution can be a significant time saver. The SaaS model shifts the responsibility of maintaining a software application from the local IT manager onto the vendor. In traditional on-premises applications, new version integration can cause severe downtime and can result in a rollback in case of a major bug in the new version.

- Scalability: If the customer’s business is growing exponentially, the software vendor must also meet the scalability needs to ensure they have access to the latest software offerings. As business grows, it can be reassuring to know that the software vendor can meet the scalability needs and help grow the capabilities in line with the customer without costly investment.

- Compatibility: For traditional on-premise software, a large workforce is typically required as it is based on the number of seats needed. One of the most talked about concerns is compatibility and version mispatch issues. Normally, any upgrade to a software represents a significant amount of time and money wasted caused by maintenance downtime. With cloud-based SaaS applications, subscribers simply sign in to access the most recent version of the application, with updates conducted online.

- Increasing business agility and fostering collaboration: With the power of the cloud, a global workforce can be brought under the same umbrella when two or more departments are in multiple countries. Similarly, suppliers who are located across the globe can be easily connected using a single system. This ability not only eliminates the silos in an organization, but truly enables close collaboration and integrated workflows that are essential for sustainable growth.

- Enabling digital transformation: Those who adopt cloud-based solutions can increase the productivity of their workforces, innovate, and unlock new sources of revenue compared to their peers. Digital transformation can accelerate business growth as a cloud-based platform can provide virtually endless possibilities. If used properly, it can help a business save money, time, and human resources. By software maintenance and incompatibility, SaaS can provide streamlined focus and greater productivity.

Expanding B2B Communication via SaaS DFM Software

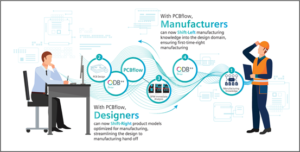

Business-to-business (B2B) networks are used to exchange data between buyers and suppliers. The communication methods vary, such as emails, communication over phone, negotiations, business deals, contracts, quotes, invoices, etc. In the PCB design-to-manufacturing handoff process, there is a need for an additional communication: the secure exchange of data for the purpose of performing design validation (DFM) at an early design phase. One solution is a networking platform for designers and manufacturers to connect and securely share data while still in the design stage. Siemens PCBflow, for example, a cloud-based software as a service solution, ensures PCB design validation against the manufacturer’s specific constraints in the early stages, thus accelerating the handoff process to manufacturing.

Business-to-business (B2B) networks are used to exchange data between buyers and suppliers. The communication methods vary, such as emails, communication over phone, negotiations, business deals, contracts, quotes, invoices, etc. In the PCB design-to-manufacturing handoff process, there is a need for an additional communication: the secure exchange of data for the purpose of performing design validation (DFM) at an early design phase. One solution is a networking platform for designers and manufacturers to connect and securely share data while still in the design stage. Siemens PCBflow, for example, a cloud-based software as a service solution, ensures PCB design validation against the manufacturer’s specific constraints in the early stages, thus accelerating the handoff process to manufacturing.

OEMs and designers can share their PCB designs, while manufacturers or EMS can share their manufacturing capabilities, reducing the need to exchange emails and transfer data for design validation to significantly reduce design spins and cycle time. By enabling DFM analysis capabilities from the world-class Siemens Valor NPI engine, subscribers can validate their PCB designs against thousands of rules instantly using pay-per-use or subscription SaaS model. Learn more at www.pcbflow.com

Yossy Pinhas has 20 years of experience in delivering hardware and software products in the telecom market. He has led products from the concept through development and production stages all the way to customer deployments. Yossy has vast expertise in product management and is an expert in translating customer pain into winning products. He holds an M.B.A. from Tel Aviv University.