Where Are the Skilled Workers for Industry 4.0?

The consensus among our industry is that the pandemic has accelerated the adoption of automation technologies. Electronics manufacturers are evaluating and implementing strategies to shorten supply chains and make their operations more resilient to future disruptions.

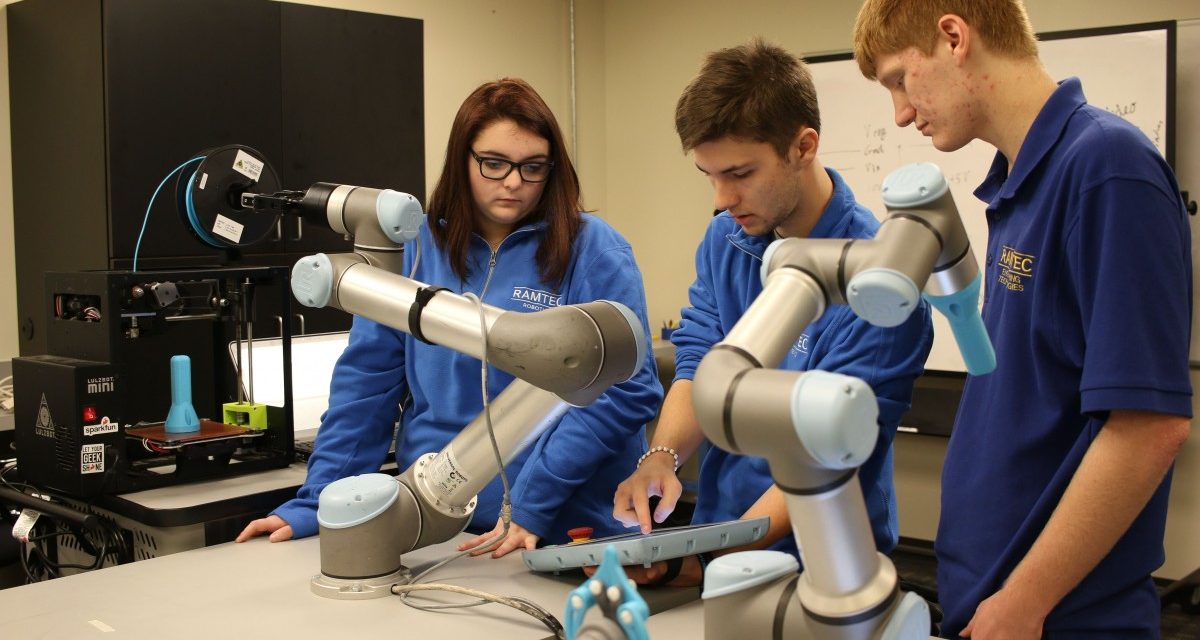

But all these efforts will require a workforce that is equipped with skills in coding and robotics. The skilled labor shortage is an even more serious barrier to the smart factory of the future than ever before. Universal Robots (UR) has taken the bull by the horns and developed a comprehensive cobot curriculum designed to train students to prepare them for careers in robotics.

As collaborative robots emerge as the fastest growing segment of industrial automation, cobot curriculum developed by an accredited provider is increasingly sought after in both schools and manufacturing industries. “With the Education Program we’re addressing a tremendous need to provide cobot training as part of an integrated, accredited course,” says Joe Campbell, senior manager of applications development at Universal Robots (UR). “This hands-on learning initiative will be instrumental in addressing the skills gap and get state-of-the art cobots into classrooms, offering students instant employability and manufacturers access to an upskilled workforce.”

As collaborative robots emerge as the fastest growing segment of industrial automation, cobot curriculum developed by an accredited provider is increasingly sought after in both schools and manufacturing industries. “With the Education Program we’re addressing a tremendous need to provide cobot training as part of an integrated, accredited course,” says Joe Campbell, senior manager of applications development at Universal Robots (UR). “This hands-on learning initiative will be instrumental in addressing the skills gap and get state-of-the art cobots into classrooms, offering students instant employability and manufacturers access to an upskilled workforce.”

Universal Robots has been accredited by the International Association for Continuing Education and Training (IACET) and is now authorized to issue the IACET CEU (Continuing Education Units). The Education Program provides a clearly defined pathway for students to master cobot programming and deployment as part of an Industry 4.0 career in robotics and advanced manufacturing. Schools can now purchase the ready-to-go package that includes the complete curriculum, a UR cobot arm, and the hardware and software required to build actual industrial applications.

Accelerates student access to cobots

The 32-hour course has been developed with assistance from Ritch Ramey, coordinator of RAMTEC, (The Robotics and Advanced Manufacturing Technology Education Collaborative) overseeing robotics training at the 24 Tri-Rivers career centers in Ohio, representing the largest, most comprehensive robotics education center in the nation. “Being able to offer a complete, turnkey training program with an industry-recognized credential gives schools increased access to both private grants and government funding when bringing cobots into classrooms,” he says. “It will make all the difference in the acceleration of student access to a real industrial robot that is both safe to operate in a classroom and easy to use.”

Upon completion of the course work, a student receives 32 course credit hours and a Universal Robots industry-recognized certification. The course can be taught in high schools, dual-enrollment courses, and in colleges.

Manufacturers can upskill workforce, attract and retain talent

The program will also be offered to manufacturers seeking certified cobot training for employees; industry professionals can attend classes either through local schools and career centers or in classes offered by Universal Robots’ authorized partners. Sending employees for certified robotics training developed by an accredited provider is often encouraged by local and state governments that increasingly reimburse companies for the training costs.

The program will also be offered to manufacturers seeking certified cobot training for employees; industry professionals can attend classes either through local schools and career centers or in classes offered by Universal Robots’ authorized partners. Sending employees for certified robotics training developed by an accredited provider is often encouraged by local and state governments that increasingly reimburse companies for the training costs.

“This is really a win-win,” says UR’s Joe Campbell. “Manufacturers struggling to attract and retain skilled workers within automation can now easily train and encourage existing staff – while employees now get a unique opportunity to receive a recognized certification that they can add to their resume for future career advancements.”

Showcased at Universal Robots’ Cobot Expo 2.0

Attendees at Universal Robots’ virtual Cobot Expo 2.0 November 16-17 were the first to see the new Education Program showcased. Building on the successful first Cobot Expo in July, the 2.0 version features floorplans organized by the most popular application segments, featuring 19 exhibiting partners, live “at the ready” demos, and 15 keynote presentations. The Education Program is featured in a dedicated booth and will be presented in the keynote “Accelerating Tomorrow’s Engineers.”

In addition to the formalized core curriculum, the Universal Robots Education Program Package consists of:

- UR Cobot Unit (UR3e or UR5e)

- 24 course licenses

- Gripper Demo Kit

- UR Academy Hardware Set:

- One conveyor assembly including conveyor, encoder, two sensors and I/O simulation test box

- Ten 3D printed training elements for exercises

- One 3D printed dual TCP

- Six 3D printed workpieces

For institutions that already have cobots, a retro package is available with course curricula, classroom support hardware and software.

Extending the Education Program to include UR+ components and application kits

Bob Graff, President of I4.0Strategies, an Education Workforce Development consultancy focused on implementing Industry 4.0 advanced automation training, career pathways and credentialing, has also been part of Universal Robots Education Program collaboration. His company is now working with several UR+ partners in developing curriculum for their products and application kits certified to work seamlessly with UR cobots.

“What separates Universal Robots from everybody else is the powerful, unique UR+ platform that enables manufacturers to build their complete cobot application by choosing UR compatible products that are tested and proven,” he says. “Bringing courses on UR+ components and kits into the umbrella of UR’s credentialed training approach will spark a revolution in educational access to these Industry 4.0 technologies.”