Using Statistical Process Control (SPC) to Eliminate Waste and Drive Your Continuous Improvement Process (CIP)

By Greg Benoit, Director of Product Marketing, Cogiscan

Greg Benoit

Statistical Process Control (SPC) is a critical tool that manufacturers in a wide variety of verticals – from pharmaceuticals to oil and gas to printed circuit board assembly (PCBA) – have used for years to better ensure their products are of the highest quality and match the intended design specifications.

Looking specifically at electronics manufacturing, with the emergence of Industry 4.0 and the connected factory, we now have access to troves of meaningful production data to elevate the SPC process. Paired with advanced analytics tools, real-time machine data, and AI-based software, these technologies enable you to react quickly to, and even eliminate, quality issues on your production floor.

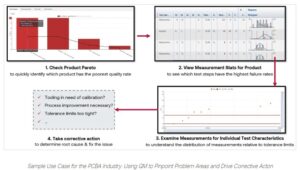

Real-Time Quality Verification

The following figure illustrates an example use case: how a PCBA manufacturer can first generate a product pareto to identify the most problematic products, then leverage the analytics tools within QM to pinpoint the precise problem, and finally drive corrective action.

Flexible Options Based on Your Electronics Manufacturing Landscape

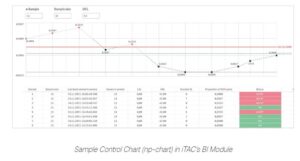

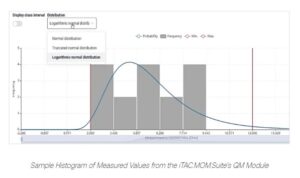

Already have an MES or MOM you’re happy with? No problem, we still have options for you. With iTAC’s modular Business Intelligence (BI) solution, you can still get access to the control charts and other SPC visualizations you need without the full MOM suite.

In this option, measurement data is collected via Cogiscan’s Co-NECT & Data Management solutions and is fed directly into the BI module for robust visualization and alarms. This enables SPC visualization and functionality without requiring you to replace or duplicate your existing MES or MOM platform. And with BI’s self-service design tools, you will also gain the added flexibility of fully customizing your own visualizations and analytics according to your specific needs and preferences.

Next-level Quality Analytics: From Descriptive to Prescriptive

While SPC is a powerful way to gain greater control of your PCBA production quality, it’s now possible to take things to the next level, with advanced analytics that go beyond descriptive and reactive methodologies. iTAC’s AI-powered IIoT.Edge platform provides all the technologies and intelligence you need to enable both predictive and prescriptive analytics.

Powerful algorithms perform streaming analytics on live data from a myriad of sources, including machine-provided defect and measurement data, as well as sensor data, to predict when quality issues will happen and then prescribes corrective actions to stop the problems from occurring to prevent defects in your products.

Robust machine learning models can also crunch massive volumes of quality data to identify patterns and determine root causes that may otherwise remain hidden from the naked eye. And as with the BI module, the IIoT.Edge can be deployed in modular fashion – with or without the iTAC Mom suite, or iTAC’s BI solution – for a truly composable architecture.