Teaching the Next Generation: IPC’s Electronics Assembly for Engineers (EAE)

As the demand for high-quality electronics products and equipment continues to grow at record rates, so does the electronics manufacturing industry. Electronics manufacturing services (EMS) are called on to deliver reliability and ingenuity in line with the industry’s ever-changing developments in technology and services. As a result, many companies are ramping up the onboarding of new engineers and technical staff into key design for manufacture (DFM), product, manufacturing, process and quality engineering roles to support high output and productivity.

But the industry is facing a skilled labour shortage, with around 80% of electronics manufacturers surveyed saying they are finding it ‘somewhat’ or ‘extremely’ difficult to hire qualified workers — and that the cost of labour has risen as a result.

The shortage of skilled labour is also causing shipping delays, with 88% of manufacturers surveyed reporting increasing lead times. With global supply chains already facing the strain of COVID and Brexit delays, the industry must, therefore, be proactive about filling skills gaps in their workforce — or else labour costs will continue to contribute to shrinking profit margins.

So, how can companies ensure the products and services being delivered at this level continue to conform to the high standards of clients and customers? The answer, according to IPC, is education.

Bridging the gap

Alongside raising wages, which 44% of electronics manufacturers say they are doing, training and education are crucial for sustaining growth in the electronics manufacturing industry.

IPC is a non-profit, member-driven global trade organisation. It represents all facets of the electronics industry and acts as a leading source for industry standards, training, industry intelligence and public policy advocacy.

According to industry leaders, their young engineers knew very little about printed circuit boards (PCBs) and printed circuit board assembly (PCBA) before entering the field. This insight comes as no surprise; education on this topic is lacking in relevant higher education courses.

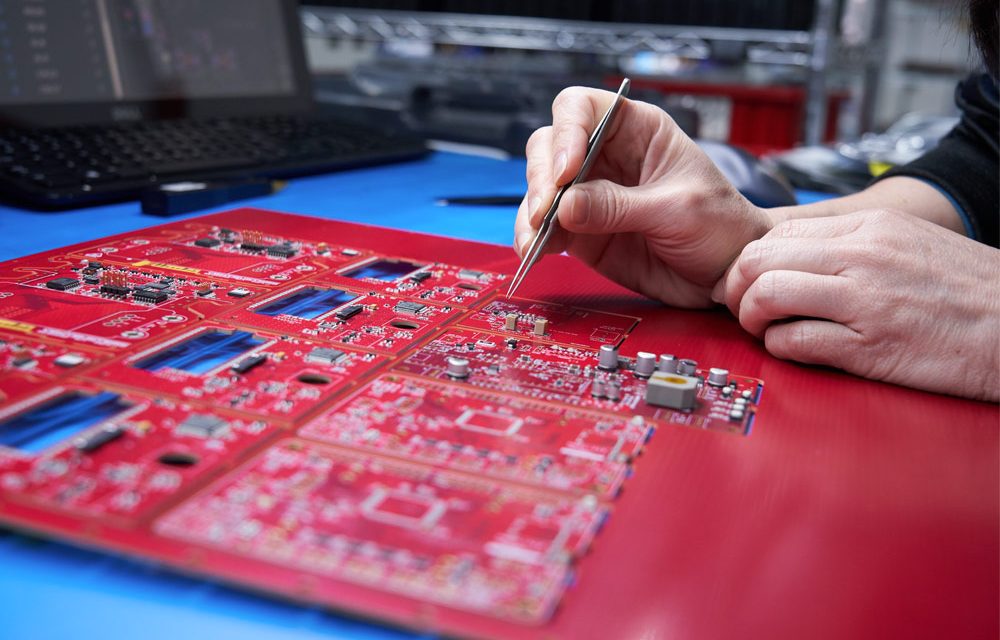

But as PCBs are so integral to the products and services driving the industry forward, organisations need to ensure their workforce has the skills to keep up. As a result, IPC has sought to fill this gap with a new course targeted at recently hired and transitioning engineers.

Electronics Assembly for Engineers (EAE) is a fully online, self-paced ‘fundamentals’ programme that will teach new hires to identify and explain the key tools, materials and processes employed to assemble PCBs within an electronics manufacturing facility.

Investing in the future of the electronics industry

Engineers make decisions every day that have an impact on manufacturing. And this course builds upon years of manufacturing experience to place new engineers a step ahead of the curve.

EAE covers the basics of through-hole, surface-mount and wire-harness technologies, starting with introducing PCB fabrication and assembly. It concludes with a detailed review of critical fundamental topics, including component identification, drawings and specifications, hand soldering, conformal coating and quality assurance.

The course is divided into 12 user-friendly modules, and the syllabus includes everything from component identification and engineering documentation to conformal coating and quality assurance. Students earn an IPC Certificate of Completion after finishing the 24 hours of course content and have three attempts to pass the qualifying test at the end.

Between July and August, over 125 engineers started their training. The breadth of new and recently hired engineers taking part — including design, test and new product introduction (NPI) — was impressive, with most students based in the UK, Europe and South-East Asia. As of early September, 60% of participants had already completed their course, and another 25% were approaching the finish line.

According to Sanjay Huprikar, president of IPC’s Europe and South Asia operations, feedback from participants has been overwhelmingly positive. Students praised the content as engaging, interactive, clearly presented and easily digestible — and found the course to be highly professional and visually appealing.

Quality products start with the people who are assembling them. But even before that comes education, so this is an exciting new development for the future of the electronics manufacturing industry.