SMTConnect Show Preview Part 2: A Holistic Approach

SMTconnect is billed as the only event in Europe that takes a holistic approach to system integration in microelectronics, offering participants a diverse program in Nuremberg from 7 – 9 May 2019. Over 400 exhibitors from 30 countries will showcase the latest products and services to around 12,000 visitors from all over the world. Three key updates for 2019:

New staging for electronic manufacturing services: EMS Park

The EMS Park, with its natural and open design, reminiscent of a park and designed with a focus on networking opportunities, is taking shape. The venue offers a small Speakers’ Corner where exhibitors can present their topics and solutions. Mr. Allois Mahr from Zollner Elektronik AG will give a lecture with the title: “Digital transformation in modern electronics production” on 7 May at 1:15 p.m.

The EMS Park, with its natural and open design, reminiscent of a park and designed with a focus on networking opportunities, is taking shape. The venue offers a small Speakers’ Corner where exhibitors can present their topics and solutions. Mr. Allois Mahr from Zollner Elektronik AG will give a lecture with the title: “Digital transformation in modern electronics production” on 7 May at 1:15 p.m.

In addition to the EMS Park, visitors will be offered the special showcase area “PCB meets Components” with exhibitors covering all aspects of printed circuit boards, components and materials. The Newcomer Pavilion will provide them with an overview of various newcomers to the industry and events and enable them to make valuable contacts.

Mechatronics & Automation Cluster

The motto of this year’s joint cluster stand is “Digitization and Robotics for the EMS Industry”. The focus of this topic, which deals with the future of electronics manufacturing in Europe, will be the exchange of experience and discussions. The cluster joint stand 5-113 invites all visitors to a breakfast reception on Wednesday and Thursday from 9:30 to 10:30 a.m. While on Wednesday the focus will be on topics relating to purchasing and procurement, on Thursday the focus will be on organization and processes.

Experience production live – the “Future Packaging” production line

The “Future Packaging” production line organized by the Fraunhofer IZM in Hall 5, Booth 5-434, will be held in 2019 under the motto “Get In The Ring – Meeting the challenges of modern manufacturing”. “The line aims to show visitors of the SMTconnect 2019 how maximum efficiency, process and technology robustness can be achieved with maximum flexibility. Each of our participants is aware of his responsibility towards his customers, interactively in close contact with them, to solve the tasks of the market”, Mr. Ulf Oestermann from the Fraunhofer IZM summarizes this year’s production line.

Visitors can experience all production steps “live” and discuss issues and challenges with experts. On its 1,000 square meters, the joint Future Packaging stand includes not only the production line but also a large number of co-exhibitors, supporters and sponsors.

The best in their field – the IPC hand soldering competition

At the annual hand soldering competition of the IPC – Association Connecting Electronics Industries from the USA, soldering professionals and young professionals will have the opportunity to demonstrate their skills on all three days of the exhibition. They compete against each other for the manual soldering of complex circuit boards and are evaluated primarily in terms of speed and precision.

The winner of the professional competition also wins a trip to the World Championship in Manual Soldering, which will take place in Munich in 2019.

SMTconnect will take place from 7 – 9 May 2019 in Nuremberg. Current information and the event tickets are available at smtconnect.com.

SEHO Systems GmbH, a leading manufacturer of complete solutions for soldering processes and automated production lines, will exhibit in Hall 4, Stand 129. The SEHO team will demonstrate the StartSelective, the perfect plug-and-produce selective soldering system, ideal for those just entering automated soldering. The machine is fully equipped to start production immediately: Simply connect, power on and produce!

The StartSelective is thought through down to the last detail, from its ease of operation that does not require special skills to many technical highlights. With a footprint of only 2.5 m², the StartSelective provides maximum quality and reproducibility of soldering results for assemblies up to 508 mm x 508 mm (20″ x 20″) and an outstanding return on investment. The compact design allows users to integrate the machine in any production island, or to place it as stan-alone system in the corner of the production floor.

The StartSelective is thought through down to the last detail, from its ease of operation that does not require special skills to many technical highlights. With a footprint of only 2.5 m², the StartSelective provides maximum quality and reproducibility of soldering results for assemblies up to 508 mm x 508 mm (20″ x 20″) and an outstanding return on investment. The compact design allows users to integrate the machine in any production island, or to place it as stan-alone system in the corner of the production floor.

While loading and unloading of assemblies is done manually, all process steps are fully automated and monitored. All process-relevant components such as the micro drop jet fluxer, preheat system and maintenance-free electromagnetic soldering unit have successfully been in use for years in other soldering systems from SEHO.

The bottom-side preheat section of the StartSelective is equipped with up-to-date pulsar heaters over the full area, which feature a high energy density and quick reaction time. An additional top-side IR preheating ensures permanent and controlled heat support during long cycles to guarantee constant process conditions.

Another highlight is the soldering area with electromagnetic soldering unit, featuring a 7° soldering angle. It is ideally suited for the use of non-wetted mini-wave nozzles with directed solder flow. The result: An ideal solder peel-off and effective reduction of possible soldering defects, even with difficult board layouts.

The solder nozzles convince with stable and reproducible flow properties, they are maintenance-free and feature a nearly unlimited lifetime, thus avoiding follow-up costs.

Just like the high-volume selective soldering systems from SEHO, the StartSelective is equipped with a complete package for automated process control. The spray jet control in the fluxing area, automatic wave height control and solder level monitoring with automated solder wire supply are only some of the monitoring functions.

The StartSelective is designed for maximum efficiency. Programming is 100 percent offline at any PC workplace so that the machine is always available for production. Simply connect, power on and produce!

The SEHO team is looking forward to welcoming visitors in Hall 4, Stand 129.

“Look further, go beyond” is the motto that Rehm Thermal Systems is using for its trade fair appearance at SMTconnect this year. Rehm developers and designers are looking to the future and are paving the way in the development of electronics manufacturing with their additional developments and optimisations in system and process engineering. This is also reflected in the systems and tools being exhibited. Rehm will be introducing the following systems at SMT 2019:

VisionXP+: The “best-in-class” system for reflow convection soldering with or without a vacuum is now even more efficient! At SMT Rehm will present the highlights of VisionXP+, for example, the use of new EC fan motors, which are not only quieter and more sustainable, but also enable comprehensive production data collection, a more effective cooling zone and design optimisation.

CondensoXC: The CondensoXC has a compact structure thanks to the innovative processing chamber and is a high-performance device. Thanks to the patented injection principle, exactly the right quantity of Galden® is supplied for optimal profiling. Thanks to the closed-loop filter system, the medium can be recovered and filtered at virtually 100%. The system is fully suitable for vacuums and has an integrated process recorder for optimal traceability.

Nexus: The Nexus vacuum soldering system is ideal for pore-free and flux-free soldering at up to 450 °C with a variety of process gases. The wet-chemical activation with formic acid is available as an option. It is possible to use lead-free or lead-containing preforms and pastes. Contact soldering is used in advanced packaging and power electronics.

Nexus: The Nexus vacuum soldering system is ideal for pore-free and flux-free soldering at up to 450 °C with a variety of process gases. The wet-chemical activation with formic acid is available as an option. It is possible to use lead-free or lead-containing preforms and pastes. Contact soldering is used in advanced packaging and power electronics.

Securo Minus: Rehm has developed the Securo range to analyse the reliability of sensitive electronics under extreme temperatures. Securo Minus is deployed in the context of the cold function test to check the winter performance of electronic assembly groups for example. The electronic components are exposed to cold air or nitrogen at low temperatures of up to -55 °C in the system and thereby brought to the optimal temperature for checking. The system can be combined with any measuring equipment.

ProtectoXP: Our selective Protecto conformal coating system protects sensitive electronic assembly groups from damage by corrosion or other environmental influences such as humidity, chemicals or dust. Rehm will be presenting a variety of application methods for different deployment areas and materials at the trade fair. They all have totally reliable and accurate coating in common to achieve the best results!

ProtectoXC: Even with minimal throughput, ProtectoXC guarantees reliable coating processes. Thanks to its compact construction, it can be integrated as a batch or line variation without any problems.

Visit Rehm at Stand 100 in Hall 4A

Indium Corporation experts, Andreas Karch, Regional Technical Manager, Germany, Austria and Switzerland, and Karthik Vijay, Technical Manager, Europe, Africa and the Middle East, will bring their industry-specific know-how to the lecture hall during SMTconnect 2019.

In addition, Indium Corporation will feature its void-reducing Indium8.9HF Solder Paste series to help customers Avoid the Void®.

In addition, Indium Corporation will feature its void-reducing Indium8.9HF Solder Paste series to help customers Avoid the Void®.

The Indium8.9HF series is a proven product that delivers no-clean, halogen-free solder paste solutions designed to produce low-voiding—plus enhanced electrical reliability and improved stability—during the printing process. Under optimal process conditions, this series:

• Exceeds all requirements for enhanced electrical reliability and SIR performance

• Demonstrates consistent printing performance for up to 12 months when refrigerated

• Maintains excellent printing and reflow performance after remaining at room temperature for one month

• Delivers excellent response-to-pause, even after being left on the stencil for 60 hours

• Resists premature flux spread to prevent surfaces from oxidizing

• Performs with both Pb and Pb-free alloys

Visit Indium Corporation in hall 5, booth 310

Nordson ASYMTEK, will exhibit its new conformal coating line and dispensing solutions , with SmartTec GmbH in Stand 4-101 and in the Fraunhofer IZM Future Packaging Line Stand 5-434. In addition, Gerd Schulze, key account manager, Nordson ASYMTEK, will present ‘Protecting Electronics — Adhesive and potting options and practical examples.’

On display will be Nordson ASYMTEK’s:

Conformal Coating Line Solution that coats, cures, and inspects. This compact, flexibly configured line delivers closed-loop process controls while saving 50% in footprint compared to other conformal coating lines.

Conformal Coating Line Solution that coats, cures, and inspects. This compact, flexibly configured line delivers closed-loop process controls while saving 50% in footprint compared to other conformal coating lines.

Vantage™ Series Fluid Dispensing System for advanced assembly technologies that involve high-speed and precise volume dispensing, tight keep-out zones, or dispensing of thin and accurate lines.

Helios™ SD-960 Large Volume Fluid Dispensing System for large volume single- and two-component applications including potting, sealing, gasketing, and structural adhesives. The system supports highly abrasive thermal interface materials (TIMs), silicones, epoxies, and grease.

“SMTconnect will be an excellent time to interact with people looking for dispensing or conformal coating equipment, application support, or solutions to their conformal coating and fluid dispensing needs,” said Michel van de Vijver, general manager EMEA, Nordson ASYMTEK. “The stringent quality demands of Europe’s automotive industry have put increased responsibility on companies to improve their processes. Nordson ASYMTEK experts at SMTconnect can help you find how to ensure your process quality.”

Find Nordson ASYMTEK at Stands 4-101 and 5-434

Saki Corporation, an innovator in the field of automated optical and x-ray inspection and measurement equipment, announces the release of its new 2Di LU1 inline bottom-side automated optical inspection (AOI) system. Saki’s 2D line-scan technology is ultra-fast, capturing the image of an entire 460x500mm printed circuit board assembly (PCBA) and carriers of 610x610mm in one pass, in real time, storing the image into memory, and creating inspection data for the entire board. This versatile system automates the bottom-side inspection process, eliminates board flipping and handling, and ensures quality after the potting, dip, wave, and selective soldering processes.

The 2Di-LU1 software includes Saki’s proprietary Fujiyama algorithm, which provides complete through-hole joint inspection in a single step. It simultaneously inspects for copper exposure, pin detection, pin-holes, solder fillet abnormalities, missing components, soldering problems, and bridges. Saki’s inspection software has been used for extra component detection of solder balls and foreign objects and through-hole device inspection in the automotive industry for several years and complies with the IPC-A-610 standard.

The 2Di-LU1 software includes Saki’s proprietary Fujiyama algorithm, which provides complete through-hole joint inspection in a single step. It simultaneously inspects for copper exposure, pin detection, pin-holes, solder fillet abnormalities, missing components, soldering problems, and bridges. Saki’s inspection software has been used for extra component detection of solder balls and foreign objects and through-hole device inspection in the automotive industry for several years and complies with the IPC-A-610 standard.

“Incorporating bottom-side AOI into the assembly process increases productivity by reducing the time, costs, labor, and floorspace needed for manual inspection, additional conveyors, or equipment to flip the board,” explained Yoshihiro Akiyama, chief technical officer, Saki Corporation. “Saki’s system speeds the inspection process, increases throughput, and eliminates extra PCBA handling and the risk of substrate damage.”

The platform and construction of the 2Di-LU1 bottom-side AOI system is based on Saki’s rigid, time-tested hardware that ensures very stable machine performance and long hardware life. The system supports L-size PCBs, high clearances, heavy substrates, and mounted jigs.

Saki will be in Hall 4, A133

Visitors to SMTconnect 2019 looking for new and innovative solutions will have the opportunity to see that “solutions” are the central theme in SEICA’s booth A4-300.

The first solution on show will be an automated board assembly line with selective soldering, visual inspection and electrical test, fully equipped with conveyors and handlers by Seica Automation.

The first solution on show will be an automated board assembly line with selective soldering, visual inspection and electrical test, fully equipped with conveyors and handlers by Seica Automation.

The Firefly Next > series, the first station in the line, represents the leading edge solution for selective soldering. Its perfect integration, on a single axis, of a high-efficiency LASER source, fully-programmable donut spot, vision system and temperature sensor, effectively redefining the levels of performance of this technology in terms of flexibility, throughput, reliability, applicability and process traceability.

After soldering, the DRAGONFLY Next > series provides optical inspection of THT components: the combination of multi-colored LED lighting and color scan camera enables detailed inspection of the solder joint meniscus and shorts detection, while the full scan acquisition of the PCB surface and not only of the components allows the detection of solder balls.

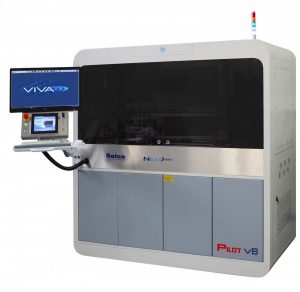

The last step in the line is electrical test, performed by the Pilot V8 Next, the most extensive flying probe test platform on the market, with up to 20 mobile resources for testing an electronic board.

The next solution that Seica will be presenting at SMT is aimed specifically for the test requirements of manufacturers of flex circuits: the Rapid H4 Next > series flying probe tester with integrated, fully automated, reel-to-reel handling and vacuum system.

In the third area of the booth Seica will propose some innovative solutions designed for today’s manufacturing realities and challenges. The use of collaborative robots (COBOTs) is gaining ground in an industry that needs to automate even in constricted spaces, and Seica’s highly configurable Compact Next > series line is able to propose diverse solutions, easy to combine with this type of automation.

All of the solutions are equipped with Seica’s VIVA Next> 64-bit software which provides a complete set of utilities and tools specifically designed to easily manage all aspects of test as well as a Test Studio, that allows the user to develop functional test sequences using whatever software is most familiar or preferred (eg. VIVA VL, VIVA Quicktest, VIVA Flylab, TestStand, Labview, MS Excel, Python).

SEICA’s booth is A4-300