Six Secrets for Strong Supplier Relationship Management

Originally posted on Jabil Blog

By Graham Scott, Jabil Vice President of Global Procurement

Open and honest communication. Transparency. Mutual support. These are the qualities of a healthy relationship…and the signs of an effective supplier relationship management strategy.

In many ways, the steps to ensure a positive supplier relationship are similar to the steps necessary to ensure a strong marriage. Both parties need to make a concentrated effort to maintain trust, transparency and communication. It doesn’t just happen accidentally; it requires deliberate and thoughtful action.

In many ways, the steps to ensure a positive supplier relationship are similar to the steps necessary to ensure a strong marriage. Both parties need to make a concentrated effort to maintain trust, transparency and communication. It doesn’t just happen accidentally; it requires deliberate and thoughtful action.

It takes company collaboration to foster corporate success and growth…especially in the unprecedented fluctuation and uncertainties of today’s global supply chain.

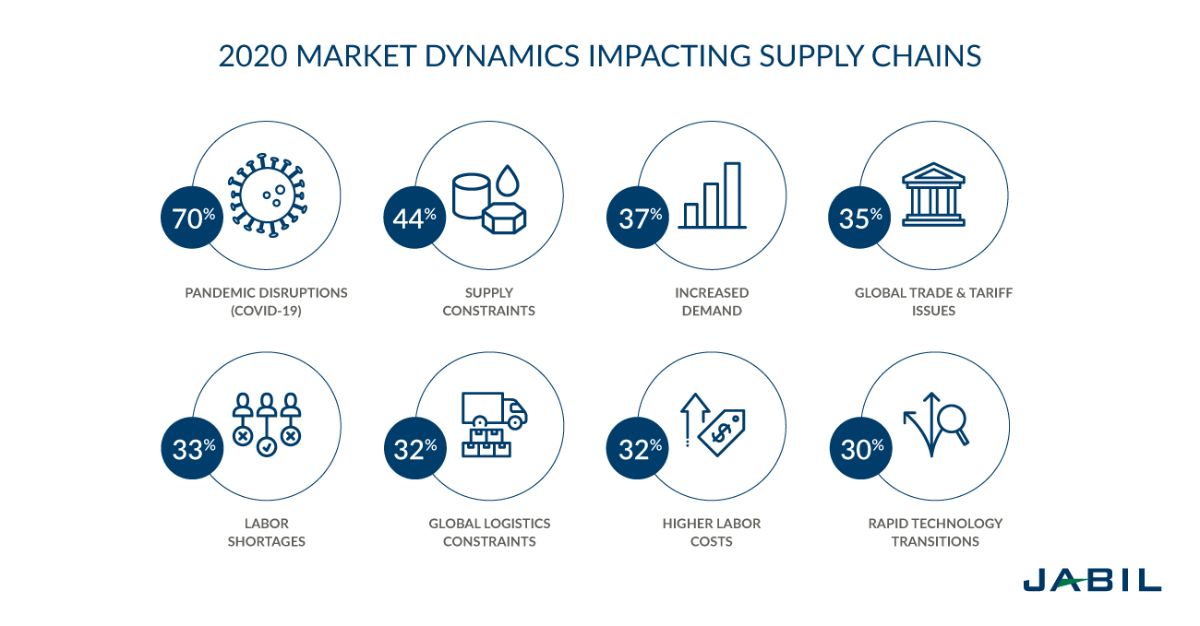

In a recent Jabil-sponsored survey of more than 700 supply chain decision-makers, respondents identified a variety of market forces affecting the global supply chain, some of the most prominent being COVID-19, supply constraints, increased demand and global trade issues.

In response to these challenges and uncertainties, OEMs are appraising their strategic suppliers and current relationships. In fact, if there’s one lesson learned from the pandemic it has been the importance of developing strategic supplier relationships.

Our survey participants indicated that the shifting supply chain landscape is causing them to take measures such as revising their approved vendor lists and evaluating multivendor sourcing strategies. Supplier relations are also shifting from traditional sourcing and procurement to rely more heavily on initiatives such as supplier relationship management (SRM).

What is Supplier Relationship Management?

To put it simply, supplier relationship management is a systematic approach for developing and managing partnerships.

The goal of SRM is to encourage mutual growth and value creation with targeted suppliers based on a foundation of trust, open communication and a win-win mindset. This differs from non-partnerships, which are predominantly governed by contract administration, contract management and vendor rating. “Purchasing and Supply Chain Management” by Robert Monczka succinctly outlines the purposes and benefits of SRM:

- Become a “customer of choice.” . Receive preferential treatment for availability, costs, access to technology, innovation and risk reduction.

- Focus on value. Increase market competitiveness through consideration of all relevant elements that determine stakeholder value.

- Leverage on supplier capabilities. Attain an advantageous position through early involvement in the innovation and product and process development processes.

- Share growth, profits, risks and investments. Develop joint objectives, efforts and resource commitments that result in a healthy culture for continuous growth.

Given the extreme number of fluctuations and uncertainties currently surrounding the supply chain, an SRM strategy is one of the most valuable investments that an organization can make. For example, about 95% of our survey participants indicated that their company has experienced the impact of the ongoing component shortages.

In an attempt to stabilize supply, OEMs are reconsidering their allocation methods. According to our survey, 44% of participants investing in supplier contingency plans, and 39% are looking for additional layers of redundancy and diversity when choosing suppliers. With this heightened focus on allocation, an SRM program is vital to compete in difficult market conditions. Overall, supplier relationships have evolved significantly over the past few years as OEMs have increasingly begun to outsource non-core competencies, thus making them more reliant on partners for innovation, security of supply, corporate social responsibility and cost savings. This dynamic is changing supplier relationships, making them more vital to bottom-line success.

So, how can you make the most of your supplier relationships?