Save money by inspecting PCBs ergonomically

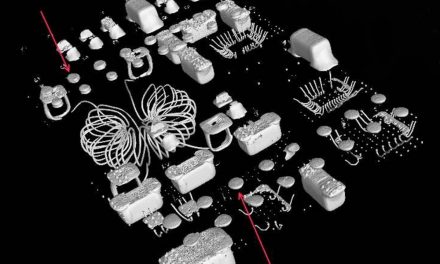

By easing physical stress and creating better work setups, human error in manual tasks can be substantially reduced, saving businesses large amounts of money. One way of doing this is by introducing digital microscopes in the PCB inspection process.

Inspecting PCBs is often a manual task performed using traditional magnifiers. However, these are also physically straining, leaving many operators with back, neck and shoulder pain as well as strained eyes. What is more, a direct link has been made between eye and back strain and increased escape of defective products during quality control. That is, by creating ergonomic work setups for PCB inspectors, there’s a lot of money to be saved for PCB manufacturers.

How digital microscopes can improve efficiency

By using a digital microscope, the operator can look at a monitor instead of through an ocular for focus. This not only reduces the risk of operator injuries by relieving them of eyestrain and neck and back pain. It also makes inspection tasks more accurate and faster by reducing operator fatigue and eliminating the need for frequent breaks. The digital microscopes can even help with non-work related injuries, e.g. from traffic accidents, and ease injured workers back into work faster.

Quick return to work after a traffic accident

Recently, a Danish microscopist hurt her head badly during a traffic accident. Instead of straining her already sore neck with a traditional microscope, the digital alternative allowed her to maintain an ergonomically correct work posture, enabling her to return to work much quicker than planned.

About TAGARNO

TAGARNO specializes in digital microscope solutions for quality control processes in the electronics industry. By combining advanced technological practices with high quality cameras and original software interfaces and apps, businesses can renew and optimize their visual inspection and quality control processes.