Productronica Opens in Munich Today – Here’s a Sample of What to See

World premieres, products, solutions and innovations along the entire value chain of electronics production and, last but not least, the best networking opportunities – that’s what productronica, the world’s leading trade fair for electronics development and production, has to offer.

World premieres, products, solutions and innovations along the entire value chain of electronics production and, last but not least, the best networking opportunities – that’s what productronica, the world’s leading trade fair for electronics development and production, has to offer.

The industry’s decision-makers and thought leaders meet at productronica to experience innovations at an early stage and at first hand. Young professionals and students, startups and professionals from small and medium-sized companies as well as the global players in electronics production make first-class international contacts here.

Swiss based Delvitech SA exhibits its latest AOI/SPI solutions based on proprietary developed AI.

Delvitech is proud to announce and show a new generation of Automated Optical Inspection systems for the electronic and mechanical manufacturing.

Electronic assembly process is moving towards more and more hidden complexity. Varied shaped parts increasing difficulties related to shadows, large components with small pins, high components with short pins continuous changeover in production due to parts availability, mix of electronic and mechanical components, combined with concurrent unplanned topics, today represent the real challenge both for cost effectiveness and quality improvement.

No matter how complex or minute the assembly is, Delvitech is addressing such challenge dedicating all its efforts in designing machines capable of superior performances. A Swiss-engineered hardware combined with a cutting edge microservices distributed software, integrated with the latest neural networks AI design, is the perfect fit for a solution to all the evolving customer needs.

No matter how complex or minute the assembly is, Delvitech is addressing such challenge dedicating all its efforts in designing machines capable of superior performances. A Swiss-engineered hardware combined with a cutting edge microservices distributed software, integrated with the latest neural networks AI design, is the perfect fit for a solution to all the evolving customer needs.

A new concept has been created, the 3iS, an Innovative, Intelligent, Inspection Solution. Enabled by the software Neith and based on Artificial Intelligence, 3iS ensures scalability and inspection repeatability on all production lines by deploying identical hardware and software technology for each inspection phase.

To show this technology, two machines named Aton and Horus will be presented in Munich from November 14th to the 17th.

Koh Young Showing PCBA and Semiconductor Inspection Innovations

Koh Young will have two booths. The first is at A2.377 and is focused on traditional surface mount technology. Our sister booth at A2.359 is focused on advanced packaging and semiconductor inspection innovations. Join our booth at Productronica 2023 to find out more. The following is just a glimpse into what Koh Young will have in store for our visitors.

Solder Paste Inspection (SPI)

In 2002, we introduced the concept of 3D measurement-based solder paste inspection – and it revolutionized the inspection industry. Today, manufacturers recognize the value of the 3D measurement data and use the data to improve the print process, in turn, improving production yield and quality. Today, 3D SPI has become a standard requirement for SMT lines – it is no longer optional.

- KY8030-3 Industry’s Fastest True3D SPI Solution with Integrated Auto-Repair Dispenser

- aSPIre3: Industry’s Highest Performing True3D SPI Solution

Automated Optical Inspection (AOI)

- Zenith Alpha Best Value True3D Automated Optical Inspection Solution

- Zenith UHS Industry’s Fastest True3D AOI Solution

- Zenith 2 Revolutionary True3D AOI Delivering Incomparable Capabilities

Automated Pin Inspection (API)

Built on its world-class True3D™ AOI technology, new enhancements help it break through barriers associated with inspecting products with a mix of both Pins and SMDs.

KY-P3 Industry-awarded breakthrough in 3D Automated Pin Inspection

Dispense Process Inspection (DPI)

- Neptune T Industry’s First 3D Optical Measurement Instrument for Transparent Materials

- Neptune C+ Award-winning True3D In-Line Dispensing Process Inspection (DPI) Solution

Process Control & Optimization Software

- KSMART Seamless Smart Factory Software Suite Turning Data into Insights

- KPO Award-winning AI-powered Printer and mounter Process Optimization Software

Semiconductor and Advanced Packaging Inspection

- Meister S Premium In-line 3D Inspection System for Micro Solder Paste Deposits

- Meister D+ Breakthrough in 3D Measurement for Highly Reflective and Mirror-surfaced Components

- Meister W+ True 3D Measurement for Wafer Bumps & Shiny Components

Meet SEHO in hall A4, stand 578!

As one of the leading companies in the industry, we are right in the middle of the action!

In constant exchange with our customers and through active participation in research projects, visions arise that we quickly implement into solutions ready for series production in order to create a competitive advantage for you.

Innovations made by SEHO: With innovative and flexible concepts, we ensure greater productivity in electronics production worldwide and we are taking another step towards zero-defect manufacturing.

Discuss with our experts at productronica 2023 how you can make your production

- efficient

- future-proof and

- sustainable,

…despite cost pressure and a shortage of skilled workers. We look forward to seeing you in Munich!

Cogiscan will help you fully harness the untapped efficiency in your factory with Manufacturing Analytics Control

Historical Analysis Flexible visualizations for in-depth historical descriptive analytics Machine- and Line-level OEE | Defect Drill-downs Placement Drill-downs | SPC

Historical Analysis Flexible visualizations for in-depth historical descriptive analytics Machine- and Line-level OEE | Defect Drill-downs Placement Drill-downs | SPC- Live Dashboards & Alerts Live dashboards & alerts to monitor availability, performance & quality Performance KPIs | Order Progress | Machine & Line Status | Live SPC | Alert Messaging

- Anomaly Detection Ad-hoc smart anomaly detection of machine and process parameters Auto anomaly detection of selected parameters & measurements

- AI & Machine Learning Powerful AI and ML platform for advanced prescriptive analytics Streaming Analytics w/ Visualizations Customer-specific Use Cases

Predict Production. Optimize Output.

Come see us at Productronica (#A3.342) to experience the future of manufacturing analytics. Covering your current & future needs in one platform, the Manufacturing Analytics Control suite covers the full spectrum of analytics. Start small, Scale fast…and leave the competition behind.

Critical Manufacturing And ASMPT SMT Unveil What’s Next For Electronics Manufacturing

Critical Manufacturing will once again join forces with ASMPT SMT, leveraging this dynamic platform to showcase its modern manufacturing execution systems (MES). The theme “Expect More from Your MES” is meticulously designed to cater to the intricate demands of the electronics and surface mount technology (SMT) industry, paving the way for Industry 4.0 innovations.

Critical Manufacturing MES is an integral part of the SMT and electronics manufacturing operation management (MOM) system, driving efficiency. It manages the entire factory, improving efficiency and material traceability through adaptable workflows. It customizes quality checks for each product, reducing costs and boosting quality, and also provides advanced analytics for spotting and preventing issues, reducing unplanned downtime, and improving overall equipment efficiency (OEE).

Critical Manufacturing MES is an integral part of the SMT and electronics manufacturing operation management (MOM) system, driving efficiency. It manages the entire factory, improving efficiency and material traceability through adaptable workflows. It customizes quality checks for each product, reducing costs and boosting quality, and also provides advanced analytics for spotting and preventing issues, reducing unplanned downtime, and improving overall equipment efficiency (OEE).

In addition to the immersive physical booth experience, a virtual tour is being offered. This virtual tour will offer a dynamic and engaging glimpse into the MES features, ensuring that the transformative journey is accessible to everyone, regardless of their ability to be physically present.

As anticipation builds for productronica 2023, Critical Manufacturing invites attendees to experience the next level of electronics manufacturing. Join us at the ASMPT booth A3.377 witness the future of MES and embark on a journey that redefines what’s possible.

IDENTCO to Showcase New Automated Wire Marking System and Enhanced Polyimide Masking Products

Ideal for applying self-laminating & flag labels to wires, company’s durable VortexID can handle up to 20 products/min and operate 24/7.

At Stand A2.557, the company will offer live demonstrations of VortexID, whose stamina and speed raise benchmarks for wire and harness label application.

In addition, IDENTCO will highlight its ability to supply labels in customized shapes and sizes for precision-dependent surface mount technology (SMT) manufacturing lines, as well as its recently enhanced series of polyimide masking products. The company’s PT Polyimide Discs comprise high-temperature film with silicone adhesive utilized for thermal and electrical insulation. The silicone adhesive’s exemplary release properties offer ample protection. The discs are provided on a liner and supplied on a core or REEL ETM for automated application settings.

Indium Corporation Introduces New Package-Attach Solder Preform Technology

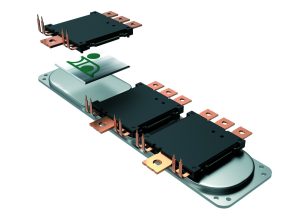

Indium Corporation® is proud to introduce a novel alloy technology that enables lower processing temperatures in preform  soldering, at Productronica 2023, Specifically developed for power module package-attach applications, Indalloy®301-LT is a bismuth-free alloy that prevents thermal defects in the module without sacrificing reliability like traditional bismuth-containing, low-temperature alloys.

soldering, at Productronica 2023, Specifically developed for power module package-attach applications, Indalloy®301-LT is a bismuth-free alloy that prevents thermal defects in the module without sacrificing reliability like traditional bismuth-containing, low-temperature alloys.

- Indalloy®301 LT Alloy for Preforms/InFORMS® – a novel Pb-free alloy that enables lower processing temperatures in preform soldering compared to SAC alloys. Specifically designed for power module applications, this alloy prevents warpage in package-cooler attach scenarios without sacrificing reliability like traditional bismuth-containing low-temperature alloys.

- Award-winning Durafuse® LT – a novel solder paste mixed alloy system with highly versatile characteristics that enable it for energy savings, high-reliability, low-temperature, step soldering, and assemblies with large temperature gradients.

- Durafuse® HR – based on a novel alloy technology, delivers enhanced thermal cycling performance (-40/125°C and -40/150°C) and superior voiding performance for high reliability automotive applications.

- Indium8.9HF Solder Paste Series – an industry-proven solder paste series that delivers no-clean, halogen-free solutions designed to achieve high surface insulation resistance (SIR) and improve stability during the printing process for high-reliability automotive electronics.

Mycronic to showcase more versatile, high-productivity assembly solutions

The MYPro I series 3D AOI, the company’s latest flagship in-line inspection system, will display its new Iris 3D AOI vision technology, which enables manufacturers to improve test coverage while capturing the industry’s highest-resolution images at speeds up to thirty percent faster than previous technologies. Visitors will have the opportunity to witness the system’s new capabilities firsthand, and learn how it helps to continually improve product quality and first-pass yield, at the Mycronic at booth A3.249 a

Escape Tracker, a real-time programming assistant that is part of the MYWizard programming software, will demonstrate entirely new levels of reliability and speed in inspection programming. A live demo will show how the software continuously scans and updates the system’s inspection library to eliminate escapes, substantially reducing false calls and consistently enhancing inspection models over time.

A pioneer in the use of machine learning in SPI and AOI, the company welcomes Productronica visitors to discuss the latest advances in neural networks and their applications for AI-assisted improvements in electronics inspection.

At Productronica, visitors will have the chance to experience the advantages of stencil printing, combined with the MY700 Jet Printer and PI series 3D SPI, which together enable add-on deposit and closed-loop solder-paste repair functionality. For manufacturers for whom the fastest cycle times are particularly critical, this add-on configuration combines the flexibility and accuracy of jet printing with the throughput of stencil printing in a single, integrated and cost-efficient platform.

“Wherever we can add new levels of flexibility, accuracy, advanced automation and easy usability, Mycronic continues to deliver value to its customers,” says Clemens Jargon, Sr VP High Flex Division. “At Productronica, we are thrilled to continue to lead the way by providing the most advanced turnkey solutions for every stage of PCB assembly.” To experience live demos and to learn more about Mycronic’s MYPro Line, software and connectivity solutions, and MYSmart dispensing and coating platforms, visit booth A3.249 a