Jabil Releases Additive Manufacturing Trends Study

A new report, sponsored by Jabil, is based on a survey of 302 individuals responsible for decisions around 3D printing at manufacturing companies with more than $500 million in annual revenues. Questions were asked on a variety of topics related to the adoption of 3D printing, as well as opportunities and challenges. Here are some key findings:

- Use of 3D printing for functional or end-use parts continues to increase; almost 55% say they use at least a quarter of their 3D printing capability to produce functional or end-use parts

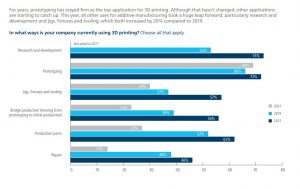

- Prototyping has stayed flat, but all other uses of 3D printing increased notably in the last two years

- Companies that manufacture production parts are more likely to have 100+ 3D printers

- Expectations for extreme growth of 3D printing continue in 2021, with 87% predicting that their use will at least double in the next five years

- 3D printing has the most impact early in the product lifecycle (i.e., design and prototyping)

- Expectations for growth of 3D printing for production remain high

- Issues with 3D printing in production continue; compared to 2019, platform issues rose 8% and ecosystem issues increased by 13%

- Organizations have not solved problems with 3D printing; scalability challenges rose 5% from 2019

- Respondents anticipate a wide range of benefits, especially ability to deliver parts quickly, lower production costs, speedy responses to production line issues and production of personalized and customized goods

- Higher level of potential benefits reported among executives

- More than half of top leadership views 3D printing as strategic

- 95% face financial barriers to the adoption of 3D printing