Intervala and Koh Young: Partners with Matching Ideals

Intervala describes itself as a “full-service manufacturer, an innovative problem solver, and a customer service champion.” That’s a pretty compelling combination and one that really resonates with the team at Koh Young. These three priorities, plus its own commitment to customer service, inspired Intervala to select Koh Young as its premier PCBA inspection partner.

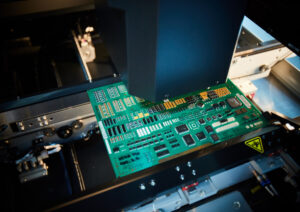

Established in 2016, but with a much longer EMS pedigree, Intervala is a full-service manufacturer of sophisticated, highly complex printed circuit board assemblies, electromechanical systems, and cable and harness assemblies. Everything the company produces is custom and tailored to their customer’s individual needs and requirements. They specialize in high-mix production that accommodates numerous product configurations, design changes, and rapidly fluctuating forecasts from customers.

Joe Benz, Intervala’s Director of Operations says, “Customers like to stop at the AOI and run through the features; it gives them a warm and fuzzy, confident feeling. They are always really impressed when we show them the analytics available on the Koh Young systems. Having that real-time data at our fingertips assures the consistent quality we are so proud of delivering.”

Intervala prides itself on combining the latest innovations with decades of experience and knowledge. It’s a combination that has served them well and helped fuel their growth through the years. The company has many customer relationships lasting more than 10 years and has built a reputation for high quality, advanced manufacturing. Intervala is headquartered in the Pittsburgh area and operates a new state-of-the-art manufacturing facility there. It has manufacturing operations in New England as well. These facilities are ITAR-compliant and hold numerous quality and workmanship certifications.

Confidence Based on Demonstrated Performance

Intervala’s journey with Koh Young began in 2018 with the addition of an SPI and AOI to one of its SMT lines. The team immediately noticed a positive impact in the line’s performance, as well as in the reaction of customers who visited the facility. As Intervala’s COO Scott Gustafson explains, “Most times, new customers or prospects have been to other EMS facilities, so they know what they have seen and what they want to see in a line. We’re in a business where perception is important. The investments Intervala has made in inspection technology show how serious we are about quality and manufacturing excellence. Koh Young inspection machines help us stand out from the pack.”

Intervala’s journey with Koh Young began in 2018 with the addition of an SPI and AOI to one of its SMT lines. The team immediately noticed a positive impact in the line’s performance, as well as in the reaction of customers who visited the facility. As Intervala’s COO Scott Gustafson explains, “Most times, new customers or prospects have been to other EMS facilities, so they know what they have seen and what they want to see in a line. We’re in a business where perception is important. The investments Intervala has made in inspection technology show how serious we are about quality and manufacturing excellence. Koh Young inspection machines help us stand out from the pack.”

It’s not just perception. The machines have improved performance on the line. Intervala historically has had excellent numbers, but now they’re even better with DPMO for termination consistently below 20 and often as low as six. For placement, the DPMO runs between 20 and 40. Much of this improvement comes because of the real-time feedback from SPI that allows the printing parameters to be automatically adjusted on-the-fly.

With all the positive feedback from operators, the quality team, and customers, Intervala says it was an easy decision to expand this level of inspection to multiple lines. Given its rapid growth, the company is considering further deployments, as well.

You Learn who your Real Partners are in a Crisis

On Christmas Eve 2019, the feeling at Intervala was anything but warm and fuzzy. There could scarcely be a worse time to have a factory flooded, but that’s exactly what happened. Intervala had to relocate to temporary accommodations in double-quick time after a failed fire suppression pipe allowed water to inundate the building from the third floor down.

On Christmas Eve 2019, the feeling at Intervala was anything but warm and fuzzy. There could scarcely be a worse time to have a factory flooded, but that’s exactly what happened. Intervala had to relocate to temporary accommodations in double-quick time after a failed fire suppression pipe allowed water to inundate the building from the third floor down.

Koh Young received Intervala’s call for help that very night and responded by getting the company’s first PCBA line up and running in the temporary quarters just five days after the incident. More lines were installed and running before the new year and, within 13 days of the flood, all of Intervala’s inspection gear was operating at full tilt again.

Scott and Joe were beyond grateful. “With our facility flooded, we needed all our major equipment partners to mobilize their troops, get them onsite, get our equipment up and calibrated, and ensure that the flood had not affected the equipment,” says Scott. Joe adds, “Koh Young’s response was just fantastic. Their people were on-site fast. I’m talking days, not weeks, and they were key in helping us recover from the catastrophe.”

Ultimately, the temporary facility became Intervala’s new permanent home, and the suppliers who responded in the company’s hour of need became even closer partners.

A holiday flood doesn’t happen every day, but according to Joe, Koh Young’s outstanding service does. “The support we get from Koh Young is exceptional,” says Joe. “Their service has been consistently outstanding, from installation through on-site training, and onto their service and support. What’s more, Koh Young’s engineers are able to log in to our systems remotely and fix most issues with little or no delay or disruption.”

Data that Drives Intelligence

The Intervala team recognizes the value of digital transformation and understands that data alone is not the solution. One of the clear value-adds the company enjoys as a result of using the Koh Young solution is the strength of the analytics provided by the KSMART software suite.

The Intervala team recognizes the value of digital transformation and understands that data alone is not the solution. One of the clear value-adds the company enjoys as a result of using the Koh Young solution is the strength of the analytics provided by the KSMART software suite.

As Joe explains, “Monitoring and analytics allow us to do more than watch and report. The data provided allows us to identify any weaknesses and focus on improvements, whether they be product, process, or system-related.”

Scott concurs, adding, “The Koh Young KSMART software solution is fantastic. It’s intuitive and allows me to run reports from my desk or remotely. It also allows us to create the dashboards each stakeholder needs to succeed.”

A Single Inspection Solution Provider

Like many Koh Young customers, Intervala desires a single inspection solution provider – one that can offer and integrate SPI and AOI solutions, as well as show a path where inspection data can be used to holistically improve factory performance.

Like many Koh Young customers, Intervala desires a single inspection solution provider – one that can offer and integrate SPI and AOI solutions, as well as show a path where inspection data can be used to holistically improve factory performance.

The Neptune, Koh Young’s latest dispensing process inspection solution, is a natural progression that adds coating and underfill inspection to a process where control can be tricky to say the least. It’s just one more step in tapping into Koh Young’s deep inspection expertise and data-driven solutions to achieve superior performance, efficiency, decisions, and outcomes for Intervala and their customers.

Summing up, Joe says, “The presence of Koh Young on the factory floor is a real game changer and differentiates Intervala for our customers, giving them confidence that we are able to deliver the quality and consistency they need and expect.”

Intervala is leveraging Koh Young’s performance and market position at a lot of different levels and values a partnership that delivers unparalleled value. At the end of the day, Intervala and Koh Young share the same ideals: delivering unrivalled, consistent, and market-leading service to customers. Together, they are doing just that.