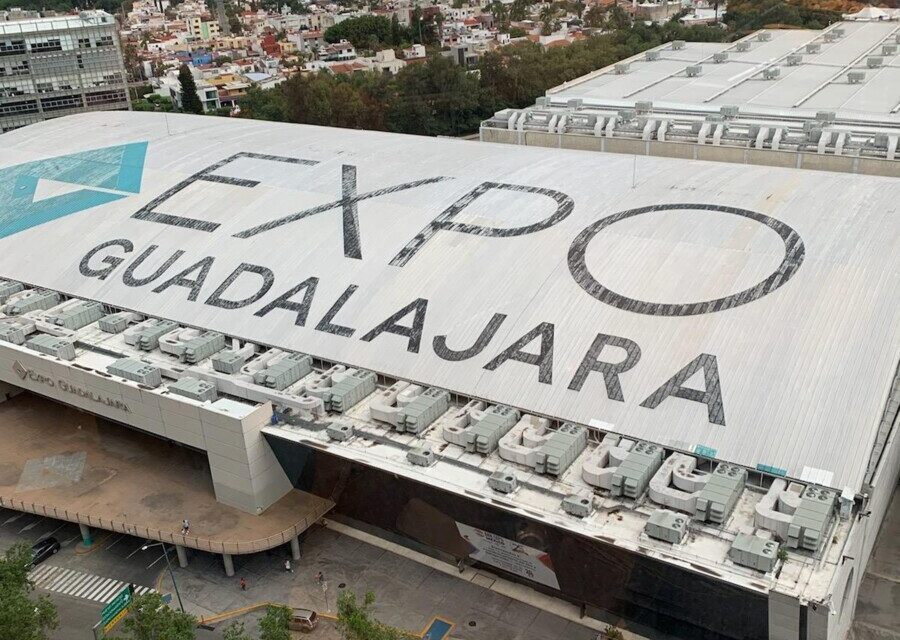

Guadalajara SMTA Expo Show Preview

Ana Maria Mendoza is currently Chapter and Events Manager – Latin America of SMTA Association. She is in charge of coordinating all SMTA events and exhibitions in Mexico, as well as public relations and customer satisfaction for the Electronics Industry for the association. Her experience in the Electronics Industry in key areas such as Manufacturing, International Trade, Logistics, Purchasing, Supplier Development and Planning makes her a valuable resource for exhibitors and presenters at SMTA events. EMSNOW caught up with Ana to get an update on this year’s SMTA Guadalajara Expo.

Ana Maria Mendoza is currently Chapter and Events Manager – Latin America of SMTA Association. She is in charge of coordinating all SMTA events and exhibitions in Mexico, as well as public relations and customer satisfaction for the Electronics Industry for the association. Her experience in the Electronics Industry in key areas such as Manufacturing, International Trade, Logistics, Purchasing, Supplier Development and Planning makes her a valuable resource for exhibitors and presenters at SMTA events. EMSNOW caught up with Ana to get an update on this year’s SMTA Guadalajara Expo.

EMSNOW: How much has the Guadalajara EXPO’s size increased compared to last year?

Year after year the number of exhibitors has grown significantly. For the last few years we have had more than 100 national and international exhibitors at the Guadalajara show. Taking into consideration the total number of exhibitors in 2023 with the current year, we have grown around 35%.

Fortunately, the interest of technology companies continues to grow and that allows us to have a quality event, which the industry users value and appreciate very much.

Just as the exhibitor base grows over time, so does the number of attendees and users, with specialists coming from all over Mexico, mainly, but also from the rest of the world. Each year we surpass our record attendance and hope to continue to do so for many years to come.

EMSNOW: How does this exhibition compare to international events?

If you are talking about specialized events in the electronics industry, SMTA Guadalajara is undoubtedly unique in Mexico. There are other events related to manufacturing, but none as specialized and focused as this show.

There are comparable events in Europe and the United States with great international recognition. Although we do not have the same traction, because SMTA Guadalajara hasn’t been around as long, we are definitely positioned within the Top 5 of the Electronic Industry fairs worldwide.

We are in a key moment for Mexico and its manufacturing, so we are advantage of this to grow as an event, but also as a community. Our main objective is to be a source of knowledge in which people at all levels, from students to global managers, can benefit from sharing experiences, insights and, of course, networking.

EMSNOW: How many years since it started, and how many other exhibitions does the SMTA Organization organize in Mexico?

This year we will be holding the 12th edition of SMTA Guadalajara and we are making more and more effort to bring leading high-tech exhibitors, which translates into high quality conferences and the exhibition of the latest technological developments.

This year we have had events in Monterrey, Queretaro, Ciudad Juarez and Chihuahua, and two more events coming up in Guadalajara on September 11 and 12 and Tijuana on November 7, as well as technical days and certifications in SMT Processes in various locations in Mexico.

For this year we are also preparing something very special exclusively for the student community. This October 10th we will be holding the first Students & Young Professionals Forum of the Mexico/Guadalajara chapter.

EMSNOW: The rumors are there are more and more foreign exhibitors. Did you see this coming? Where are most of these companies from?

No, this has definitely been a big surprise. When we started with the events in Mexico they were on a smaller scale and in a table top version, where mostly Mexican companies participated.

I could say that from five years to date we have had an exponential growth and that has put us in the focus of regions even outside Mexico. This year we have the participation of several companies from China, Korea, and of course the United States. We think it is great, because for us it is a clear indication that we are doing things right.

EMSNOW: What can we expect in the next few years?

Every year we strive to provide events of greater quality and scope, so we hope to continue advancing with this initiative to continue growing and positioning Mexico as a leading exponent in the sector.

I also want to acknowledge that it is thanks to the support of all the officers that this growth and positioning has been possible. They are the ones who ultimately provide their time, knowledge, commitment and professionalism to make SMTA Mexico a success and an invaluable contribution to the industry in our country.

I want to thank first of all the officers of all the chapters in Mexico for their enormous support during this time. And of course to all the users and exhibitors for believing in us and showing their interest in our initiatives.

Finally I would like to invite you to follow closely the Mexican chapters to be aware of future events:

SMTA Mexico/Guadalajara Chapter: https://smta.org/group/mexico-guadalajara

SMTA Mexico/Juarez Chapter: https://smta.org/group/mexico-juarez

SMTA Mexico/Queretaro Chapter: https://smta.org/group/mexico-queretaro

SMTA Mexico/Northeast Alliance: https://smta.org/group/mexico-northeast

Exhibitor News

Koh Young will be in attendance this week, exhibiting at booth 702.

- KY8030-3 Industry’s Fastest True 3D SPI Solution with Integrated Auto-Repair Dispenser

- KPO Printer Award-winning AI-powered print process control software

- Zenith AlphaBest Value True 3D Automated Optical Inspection Solution

- Neptune C+ Award-winning True 3D In-Line Dispensing Process Inspection Solution

- KY-P3 Best-in-class Measurement Accuracy and Inspection Reliability

- KSMART Smart Factory Software Suite Turns Data into Insights

Ramiro Mora, Koh Young Application Team Leader for Mexico and South America, will present on solder paste print process capability analysis.

Ramiro Mora

Statistical Process Control (SPC) is essential for real-time monitoring and control of processes. By utilizing statistical tools and charts, SPC helps detect changes, trends, and patterns in output over time. In the context of solder paste printing on printed circuit boards, SPC evaluates process performance to ensure quality and determine when adjustments are needed. The primary aim of SPC is to prevent issues before they arise, leading to significant savings and improvements in operations through data-driven decisions.

Indium Corporation to Highlight High-Reliability Solder Solutions

Indium Corporation will showcase the following among its featured products:

- Durafuse® LT is an award-winning solder paste alloy system with versatile characteristics that enable energy savings, high reliability, and low-temperature step soldering. It’s ideal for assemblies with large temperature gradients and large BGAs with complex warpage profiles. Durafuse® LT delivers superior drop shock performance, outperforming conventional low-temperature solders like BiSn or BiSnAg alloys, and even outperforms SAC305 with optimal process setup.

- Durafuse® HR, based on novel solder paste alloy technology, delivers enhanced thermal cycling performance (-40°C/125°C and -40°C/150°C) and superior voiding performance for high-reliability automotive applications. It also offers reduced solder joint cracking and increased shear strength.

- Indium8.9HF Solder Paste Series is an industry-proven solder paste series that delivers no-clean, halogen-free solutions designed to achieve high surface insulation resistance (SIR) and improve stability during the printing process for high-reliability automotive electronics.

- CW-818 is a flux-cored wire is designed to meet the demanding requirements of today’s manual and robotic soldering processes. CW-818 provides fast wetting speeds, allowing users to minimize cycle times. The spatter control technology minimizes flux spattering while the heat-resistant nature of the formula reduces flux build-up on the soldering iron tip as well as leaves a clear, non-tacky residue post-soldering (even when using a high iron tip temperature). The superior soldering performance, improved cleanliness, and excellent visual appearance post-soldering deliver a truly no-clean flux-cored wire.

To learn more about Indium Corporation’s solutions, visit their experts at booth #430 at the show.

AXXON Mycronic introduces new Guadalajara subsidiary.

EMSNOW learned about dispensing solutions provider Axxon Mycronic from Jeff Leal, Director of Business Development and Strategy. The discussion starts with background about the history of Axxon, which was originally a Chinese company and was acquired by Mycronic in 2016. Now the plan is to bring these comprehensive dispensing solutions to the rest of the world, starting with the new subsidiary in Guadalajara, Mexico.

Watch video here

Cybord demonstrates software solution at Fuji booth

Oshri Cohen, CEO of AI-based software provider Cybord, explains to EMSNOW how their solution finds non-conforming material coming into the PCB manufacturing process. In the past year a lot has happened in this arena and Oshri outlines the trends: EMS companies have been much more open to adoption of this groundbreaking technology to prevent not only counterfeit components but any defects arising from bad transportation or storage practices. EMS and OEMs are increasingly looking for ways to automate the inspection process to ensure their AVL and restrictions on country of origin requirements are adhered to. Oshri shares a video about a new solution – Real-Time Interceptor (RTI) – that will be available later this year. He invites EMSNOW readers to visit Cybord at SMTA Guadalajara Expo this week at the Fuji booth.

Watch video here