Fraunhofer Future Packaging Line at SMT Connect 2019: A Manufacturing Solution is Realized

By Oren Manor, Director of Business Development, Mentor, a Siemens Business

Oren Manor

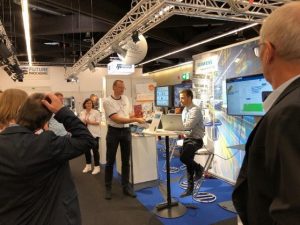

At the SMT Connect 2019 event in Nuremberg, Germany, the “Future Packaging” live production line organized by Fraunhofer IZM (in Hall 5, booth 5-434) was featured. The Future Packaging line is comprised of the latest machine and process technologies from many key companies in the industry. The Future Packaging line executed real production during the show, highlighting the individual advanced process capabilities from each of the machines, enabling visitors to see the technologies in an actual operational environment (Fig. 1).

Fig. 1: Crowds gathered at the Fraunhofer Future Packaging live production line at SMT Connect 2019.

Choosing the “best tool for the job” can be an important differentiator for success in electronics manufacturing. Unlike other manufacturing industries, electronics comprises a vast range of product types and classifications, from simple “throw-away” devices to safety/mission-critical systems – throughout the many industrial sectors in which electronics now plays a key part. This demonstration production line shows how machines from many different vendors need to work together, each providing their unique capabilities and services. Visibility of what is happening second by second on the line as a whole is crucial. Industrial engineering, product flow, material supply, and quality management traditionally have all been performed mostly by manual methods, but the Fraunhofer Future Packaging line relies on the Open Manufacturing Language (OML) standard for automated machine-to-machine communication. OML is a free, open standard that provides a single, normalized, vendor-neutral communication interface for PCB assembly Internet of Manufacturing solutions.

The OML specification facilitates information from production processes, gathered in real-time and applied to real-world manufacturing shop-floor solutions such as finite production planning, Lean material management, quality management, and full materials and production traceability. Unlike previous machine-communication standards, OML features bi-directional data flows for shop-floor data creation and process control, all through a single standard format, language, and protocol through one standard interface, rather than many different interfaces. Development cost and lead-time for PCB assembly shop-floor projects for advanced manufacturing computerization can be significantly reduced using OML, removing the barriers for entry for many companies and allowing them to respond to evolving industry business demands.

Fig. 2: The Open Manufacturing Language (OML) and Valor IoT Manufacturing hardware were used to connect to all of the machines in the Fraunhofer live production line.

For the Future Packaging line, the OML (developed by Mentor Graphics and donated to the industry: www.omlcommunity.com) allows each machine vendor to connect existing machines together using the latest IoT technology. Each participating machine in the Fraunhofer line used a Valor IoT Manufacturing hardware networking interface embedded to the machine, enabling the exchange of information about the machine’s operation (Fig. 2). Ethernet cables connect all of the machines together, which is then connected to a gateway through which any external system or application can access the data in real time.

At the Fraunhofer Future Packaging Line, the entire assembly process, including the subsequent test procedures, featured data on series of screens above the machines (and also accessible on mobile devices). Siemens (Mentor’s parent company) provided a showcase area, where data was presented on a live operational dashboard, together with a demonstration of real-world Industrie 4.0 site-level solutions (Fig. 3).

Fig. 3: Siemens presented performance data on a live operational dashboard of the Fraunhofer Future Packaging line at SMT Connect 2019 in Nuremberg.

Omnidirectional Data Flow is Crucial

An essential part of the IoT structure is that data does not just flow in one direction – true IoT data flow is omnidirectional. Individual machines can take data from other processes in the line, or from site-based resources that may include such data as live production status and flow, work-order sequence, product and process setup data, material and logistics, quality information, or any other form of inter-process communication. Each machine vendor is in the best position to create and provide Industrie 4.0 solutions related to their respective technology. Barriers no longer exist betweencombinations of machines, including different customizations in the production line.

Fig. 4: OML enables different machines to perform efficiently and synergistically using a single vendor-neutral communication interface.

The machine vendors’ solutions coexist and support each other in the line. In turn, complementary functions provide data down to the machine level that describe site-based operations such as product data, planning, and materials, including monitoring the live data from the machines, and results or requests from the machine Industrie 4.0 functions. It is a synergistic environment in which many companies can work together to provide complementary, niche solutions, promoting opportunity and positive competition, which means greater choice for customers.

Examples of the various data content that flows through IoT using OML include:

- Equipment configuration

- Equipment status (events, modules, lanes, shared feeders)

- Item data as it moves through the equipment (consumption, cycle times, type: PCB, buffering)

- Recipe data (also known as a program)

- Intelligent feeders

- Equipment control (commanded remotely to perform specific actions)

- Component handling from supply to placement (detects error and events)

- Manufacturing execution system (MES) material integration

- Item traceability data (including results from processes: pass/fail, inspection, test, fault codes, digital test, process parameters, repair tickets)

- Identification of products, materials, tools, equipment and other resources (using barcode labels, RFID tags, or other markings)

- General messages (configuration, vendor interface version, system and machine health, debugging, etc.)

- Quality management (test and inspection equipment manual repair stations)

- Environment (data from any sensors for temperature, humidity, light levels)

Conclusion

The Fraunhofer Future Packaging Line showcased the first, open, real-world manufacturing demonstration of the digital IoT solution for electronics SMT and assembly production. The use of OML and the Valor IoT Manufacturing hardware provides a standard IoT platform and infrastructure where information between all processes and systems can be shared in a vendor-independent manner. Visibility of the data using dashboards shows the wide scope of available information; machine vendors in the line can access all of the data throughout the line and factory and contribute data as a whole from their respective processes. As well as cost savings, machine vendors can create Smart process improvement and Industrie 4.0 solutions of their own, specific to their machine technology, while offering the customer additional value through add-on options to the machines. Information about production progress and changing delivery-demand requirements that drive changes in the plan day-by-day can be effectively and immediately communicated to machines so that the local machine software can prepare for optimized changeover cycles. Communication with enterprise systems, for ERP, ERP, MOM, or PLM, is enhanced, providing live feedback of material consumption, production progress, and a complete digital product build record for each product made.