Exhibitor Highlights – SMT Hybrid Packaging Nuremberg June 5-7

With no Productronica this year, SMT Hybrid Packaging will be the premier event in Germany for the electronics manufacturing sector. The show, taking place in Nuremberg between June 5th and 7th, will be the venue of numerous discussions around Industry 4.0 and other major topics for the industry. The show also provides a unique insight into the current state of the German domestic market.

Here are a few exhibition highlights for this year’s event. If you missed your company being featured in this preview and would like to be in the next one, please email editors@emsnow.com.

Aegis Software, a global provider of Manufacturing Execution Software (MES), will showcase the latest release of their true Industry 4.0, digitalized MES software, FactoryLogix. Aegis will also be a key participant in the show-wide, live, IPC Connected Factory Exchange (CFX) IoT demo.

Aegis Software, a global provider of Manufacturing Execution Software (MES), will showcase the latest release of their true Industry 4.0, digitalized MES software, FactoryLogix. Aegis will also be a key participant in the show-wide, live, IPC Connected Factory Exchange (CFX) IoT demo.

The achievement of Industry 4.0 digital factory operation requires three critical elements, all of which Aegis will have on their stand 150, Hall 4 at the show. The first is the introduction of the new IoT-based industry standard for the live and secure exchange of data between machines and processes, IPC’s CFX. In its European debut at the show, data will be gathered live from multiple machines and vendors across the entire show-floor, and made available to every show visitor simply by looking at straighforward metrics and analytic reports delivered to their mobile phones.

The second critical element for the achievement of Industry 4.0 is to have MES software that is specifically designed for Industry 4.0 and IoT technology. Aegis’ FactoryLogix software is unique in this respect, the latest release of which features many new and improved functions, including the integration of Administrative Quality Management, which combines CAPA (Corrective And Preventive Action ) and FRACAS (Failure Reporting, Analysis, and Corrective Action System). The real value of Administrative Quality Management is that unlike in-process quality tools that ensure that every product is shipped without defects, administrative quality actually automates corrections and continuous improvement procedures such that defects don’t occur in the first place. Together with the existing automated symptom and defect data collection and reporting capabilities, FactoryLogix provides a unique and complete world-class quality solution.

The third critical element for Industry 4.0 is the understanding of the business case and operational goals that utilize the latest technology to its fullest extent. Experts in Industry 4.0 for business and strategy will be available for one-on-one discussions at the Aegis booth.

Indium Corporation will feature its ultra-reliable Indium8.9HF Solder Paste. Indium8.9HF Solder Paste is an air reflow, no-clean solder paste specifically formulated to accommodate the higher processing temperatures required by the SnAgCu, SnAg, and other alloy systems favored by the electronics industry. The Indium8.9HF series delivers no-clean, halogen-free solder paste solutions designed to produce low-voiding—plus improved stability—during the printing process. Indium8.9HF:

- Demonstrates consistent printing and reflow performance for up to 12 months in refrigerated storage

- Maintains excellent printing and reflow performance after remaining at room temperature for one month

- Delivers excellent response-to-pause printing performance even after being left on the stencil for 60 hours

With all these qualities, Indium8.9HF solder paste is able to enhance the reliability of the final product in three ways:

- Improved thermal conductivity and thermal reliability with industry-proven low-voiding performance

- Enhanced mechanical reliability when paired with Indium Corporation’s newest high-reliability alloy, Indalloy®276, which allows for a stable and consistent performance under a harsh environment (Indalloy®276 is ideal for operating temperatures equal to or greater than 150°C)

- Higher electrical reliability with an enhanced SIR. For more information about Indium8.9HF Solder Paste and its use in automotive electronics, visit www.indium.com/avoidthevoid or stop to see us at the show at booth #4-301.

Under the slogan “True 3D Smart Factory solutions powered by the AI platform,” Koh Young Technology will exhibit in Hall 4A, Booth 233, at the upcoming SMT Hybrid Packaging show scheduled for June 5-7, 2018 at the Messe in Nuremberg, Germany. The company will display the next-generation Zenith2 3D AOI, new KY-P3 3D pin inspection solution, and the new automated solder dispensing feature on its KY8030-3 3D SPI.

At the show, Koh Young will demonstrate its Zenith2 3D AOI, which inspects a wide range of components with side-view camera solutions. The next-generation 3D AOI platform in the Zenith series, the Zenith2 recently earned SMT China VISION Award for its innovation. This user-friendly, smart 3D AOI was designed with Industry 4.0 in mind. Some new features include AI-powered Auto Programming, which automatically configures inspection conditions and yields a 70 percent reduction in programming time and OPO@KSMART (Offline Program Optimizer) to automatically define and deploy modified inspection conditions without interrupting production.

At the show, Koh Young will demonstrate its Zenith2 3D AOI, which inspects a wide range of components with side-view camera solutions. The next-generation 3D AOI platform in the Zenith series, the Zenith2 recently earned SMT China VISION Award for its innovation. This user-friendly, smart 3D AOI was designed with Industry 4.0 in mind. Some new features include AI-powered Auto Programming, which automatically configures inspection conditions and yields a 70 percent reduction in programming time and OPO@KSMART (Offline Program Optimizer) to automatically define and deploy modified inspection conditions without interrupting production.

Koh Young will also display its enhanced 3D SPI system with an innovative integrated solder paste dispensing function called Auto-Repair. The high-precision, user-friendly dispensing system helps to eliminate costly mistakes from insufficient solder that contributes to open joints, lean fillets, and weak joints. While the KY8030-3 inspects solder paste with the highest possible speed and precision, it can now repair insufficient solder defects before leaving the machine. With this new feature, manufacturers realize an enhanced first pass yield and reduced operational costs.

Leveraging its strength in robotics and 3D measurement, Koh Young will also highlight the new KY-P3 inspection solution. The Koh Young KY-P3 allows manufacturers to measure and inspect a wide range of pins, including single pin, press-fit, fork-pin, and connectors. Using 3D measurement, the KY-P3 ensures the pins are correctly aligned for the designated through-hole openings in the circuit board. Thanks to Koh Young’s superior 3D imaging technology, the system measures with ±0.75% pin height accuracy.

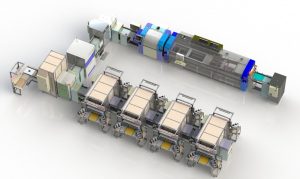

SEHO Systems GmbH, a worldwide manufacturer of complete solutions for soldering processes and automated production lines, will focus on equipment productivity in Hall 4, Stand 141 at the upcoming SMT/Hybrid/Packaging show, scheduled to take place June 5 – 7, 2018 at the Messe in Nuremberg, Germany.

With the aim to make the production process in electronic manufacturing more efficient and to reduce production costs sustainably, SEHO extended its range of automation solutions in recent years. The products range from board handling with conveyor systems to connect various machines and work places in production lines, buffer systems, turn stations, e.g. for changing the direction in manufacturing lines, lift stations, as well as transfer units and many more.

Work places made by SEHO are ergonomically designed and individually adjustable in height to be adapted to different operators. All of the connected stations such as buffers or conveyors adjust their height automatically. In addition, a particular focus is on cobots and robots that are housed in a multifunctional production cell. This cell can be equipped individually so that the robot may take over several tasks: For component placement, for assembly and disassembly of component downholders, for loading and unloading of carriers, for precise positioning of boards for AOI and electrical tests, and for removal of reject parts.

Combined with the innovative soldering systems from SEHO, users benefit from complete solutions that are perfectly matched both technically and in regards to production flow. SEHO assists customers with creative ideas in the planning phase to best meet the individual production challenges, and constructs and manufactures the production line to provide customized automated solutions.

At the show, SEHO also will introduce the completely redesigned flagship PowerSelective for the first time. This selective soldering system offers the highest flexibility at simultaneously large production volumes with minimum footprint requirements. The latest generation of PowerSelective presents itself with many new features, including a gripper system that automatically can be turned 360° thus leading to remarkable cost savings in multi-wave processes, or an integrated AOI system that ensures reliable soldering results without influencing cycle time.

Fume extraction vendor ULT AG will introduce a unique system concept. The ULT 200 systems help to remove soldering fume (LRA series), dust and smoke (ASD series) as well as odors, gases and vapors (ACD series). The modularly designed units can be equipped with additional filter modules, e.g. for higher amounts of air pollutants or with activate carbon. Furthermore, a variable number of capturing elements such as extraction arms, tubes or hoses can be installed per unit. Utilizing latest electronics that enables an automatic vacuum stabilization and selectable pressure range, ideal extraction performance is guaranteed also for several workplaces. Hence, the units are capable of maintaining the required performance level even if there are several capturing elements attached to the system.

Fume extraction vendor ULT AG will introduce a unique system concept. The ULT 200 systems help to remove soldering fume (LRA series), dust and smoke (ASD series) as well as odors, gases and vapors (ACD series). The modularly designed units can be equipped with additional filter modules, e.g. for higher amounts of air pollutants or with activate carbon. Furthermore, a variable number of capturing elements such as extraction arms, tubes or hoses can be installed per unit. Utilizing latest electronics that enables an automatic vacuum stabilization and selectable pressure range, ideal extraction performance is guaranteed also for several workplaces. Hence, the units are capable of maintaining the required performance level even if there are several capturing elements attached to the system.

However, the overall system concept with a wide range of accessories provides the greatest added value. It includes a food switch, suction hoses, Y-tube pieces, sleeves, reductions and a bracket for extraction arm installations. The well-thought accessory range has been specifically designed for the ULT 200 system series, helping to reveal the systems‘ full economic and applicational benefits.

Visitors to ULT’s trade show stand may get first-hand information on the new system range’s high flexibility and variability, receiving concrete conclusions on potential applications as well as purchasing and maintenance cost savings.

ULT’s fume extraction systems provide for clean air in production processes. They sustainably protect employees, manufacturing plants and products from hazardous airborne contaminants occurring during the utilization of laser systems, soldering equipment as well as gluing, laminating and coating technologies. The ULT 200 extraction systems are designed for medium quantities of pollutants; provide long filter life times, easy-to-handle and low-noise operation. Visit ULT AG at SMT 2018: hall 5, stand 212