EMSNOW Mexico Executive Interview – Manuel Munguía, AIM Solder Technical Support Manager – Mexico & Latín America

Manuel Munguia, Technical Support Manager for AIM Solder in Mexico and Latin America, is a Certified IPC specialist with over twenty years of experience in the solder assembly materials industry. Manuel supports key corporate accounts in Mexico, Central, and South America. Manuel graduated with a broad background of studies in Electronics and Computer Engineering from the Centro de Enseñaza Tecnica Industrial (CETI) in Guadalajara, Mexico. He is also a Certified Lean Six Sigma Black Belt. A member of the SMTA, Manuel obtained his SMT Certification as Process Engineer (CSMTPE) in 2016. We caught up with Manuel to hear his insights about business conditions there now.

EMSNOW: Tell us about AIM Solder’s business in the electronics industry in Mexico. What end markets do your electronics industry customers represent?

AIM Solder has positioned itself as a key player in Mexico’s electronics industry, which is a rapidly developing market within the global arena. Our customers span across a diverse array of end markets, including but not limited to automotive, aerospace, and consumer electronics. The common thread among all these sectors is the need for high-quality solder products and processes that can enhance reliability and performance.

AIM Solder has positioned itself as a key player in Mexico’s electronics industry, which is a rapidly developing market within the global arena. Our customers span across a diverse array of end markets, including but not limited to automotive, aerospace, and consumer electronics. The common thread among all these sectors is the need for high-quality solder products and processes that can enhance reliability and performance.

AIM’s commitment to the Mexico electronics industry is unequalled. AIM has had full-line production capabilities in Mexico for over two decades. AIM is uniquely positioned to support both EMS and OEM manufacturers with products produced in Mexico, ensuring a robust supply chain while offering the training and technical support needed to ensure AIM products produce best possible results.

EMSNOW: What type of support do you provide to AIM Solder customers? What kind of problems are you seeing these days?

Our support encompasses a wide range of services, from process development and troubleshooting to operator training and even scrap reclamation. Challenges related to miniaturization and the increased complexity of electronic assemblies require a deep understanding of soldering materials and processes to ensure we maintain the responsiveness and product reliability that our customers expect.

EMSNOW: What do you see as the strengths of the EMS industry in Mexico from your perspective?

One of the key strengths of Mexico’s EMS industry is its dedication, agility and responsiveness to change. The workforce is both skilled and adaptable, embracing new technologies and methodologies with ease. Furthermore, the proximity to United States markets, provides a strategic advantage in terms of logistics and supply chain efficiencies.

EMSNOW: What are the challenges?

The challenges are multi-faceted, but the most pressing are remaining competitive with other markets in terms of cost, efficiency and product quality. Additionally, navigating the complexities of international trade agreements and regulations remains a significant hurdle for the industry.

The challenges are multi-faceted, but the most pressing are remaining competitive with other markets in terms of cost, efficiency and product quality. Additionally, navigating the complexities of international trade agreements and regulations remains a significant hurdle for the industry.

EMSNOW: How will the industry find all the skilled workers it needs to ramp up in the Americas to provide an alternative to China? What is AIM Solder doing to encourage young people to choose manufacturing careers?

Developing a skilled workforce requires a concerted effort in education and training. We work with organizations like SMTA and IPC to support their outreach and educational initiatives. By showcasing the technological advancements and career opportunities within the industry, we aim to attract more young people to the manufacturing sector.

EMSNOW: How do you see the market growing in Mexico in the next few years? What are the drivers?

The market in Mexico is poised for significant growth, driven by the global demand for consumer electronics and the ongoing trend of reshoring and nearshoring of manufacturing operations. We are also seeing a rise in the automotive sector’s demand, particularly with the advancement of electric vehicles.

EMSNOW: What new products/services is AIM rolling out this fall? Do you have any previews?

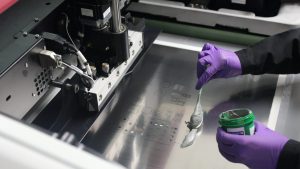

AIM Solder is always innovating, and this fall is no exception. In fact, we are revealing a new Ultrafine No Clean Solder Paste at Productronica designed to meet the increasing demand for fine pitch pastes that can print and reflow the fine feature devices including micro and mini-LED to die attach and more. Additionally, we’re enhancing our support services with more online resources and an updated website that will go live before the end of the year.

AIM Solder is always innovating, and this fall is no exception. In fact, we are revealing a new Ultrafine No Clean Solder Paste at Productronica designed to meet the increasing demand for fine pitch pastes that can print and reflow the fine feature devices including micro and mini-LED to die attach and more. Additionally, we’re enhancing our support services with more online resources and an updated website that will go live before the end of the year.

EMSNOW: What else would you like to say to EMSNOW readers?

I want to emphasize AIM Solder’s commitment to the electronics industry in Mexico and globally. Our mission, vision, and values are not just words; they are the guiding principles that drive our every action. We strive to be your trusted partner, committed to innovation, quality, and exceptional service.