EMSNOW Executive Interview: Ivan Romo SMarTsol Technologies’ General Manager

As we have reported here before, Mexico is benefitting from the trend for electronics manufacturers to move closer to their end customers to save on overall manufacturing costs, logistics costs and transit times. More recently, the trend has accelerated to mitigate risks due to the pandemic and other geo-political issues. Mexico is considered a strategic trade partner to the United States for its capabilities and proximity. The electronic assembly industry has been active in Mexico for more than 40 years and, like the industry around the world, it continues to be transformed to become more competitive. The industry transformation also pushes the growth of all the areas involved in the economic growth of the country.

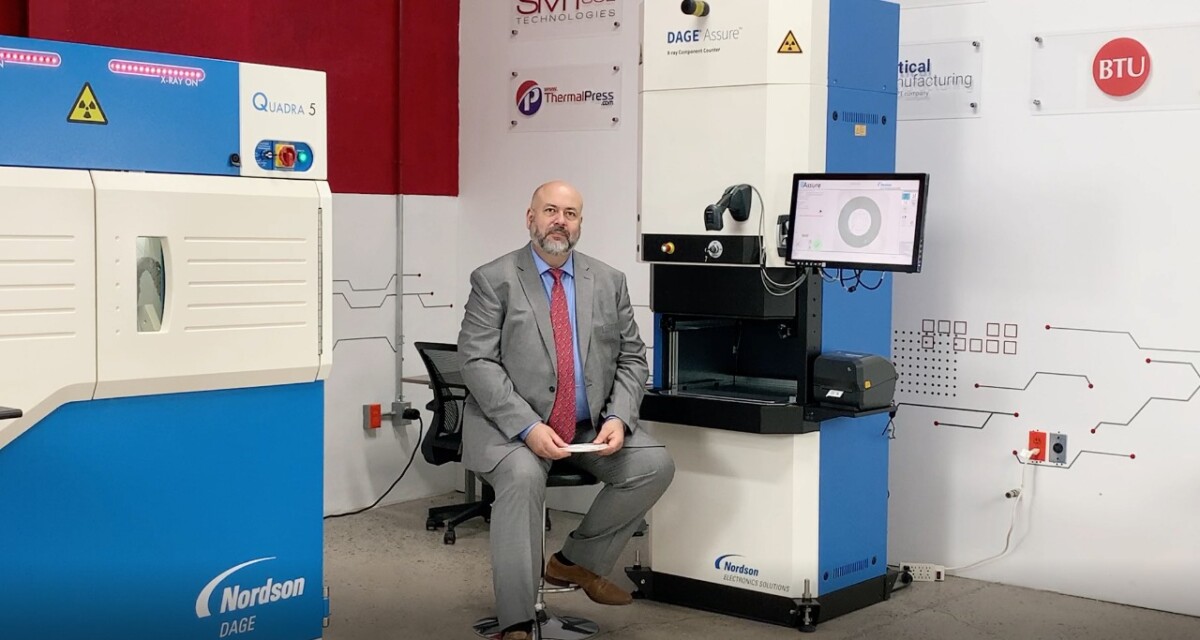

Ivan Romo, SMarTsol General Manager

SMarTsol, as one of the largest providers of capital equipment and consumables for this industry, has also been preparing for growth by improving the capabilities of each of its distribution, demonstration and training centers. Their largest facilities are in Guadalajara. Recently they have opened a new facility and we caught up with Ivan Romo to learn more about it.

EMSNOW: Where is the new SMarTsol center and when did it open?

Demo room

SMarTsol’s Guadalajara locations, April 2022. Our demo and training room is equipped with a Test & Inspection Lab with AOI, ACI and X-Ray capabilities, cleanliness testing lab with spray in air, ultrasonic, PCB cleaning efficiency testing capabilities, cleaning process characterization and analysis.

This facility has many others capabilities including robotic soldering, robot screwing, robotic dispensing, automation lab and all the equipment to run test and validation for printing, reflow, fluxing, routing, laser marking and laser cutting, and more.

All this infrastructure helps to provide the best capabilities to develop applications and training for all our customers.Each day we receive at least one group of customers who take advantage of our capabilities.

EMSNOW: Why did SMarTsol decide to do this, what was the need? And how did Covid impact the planning and execution?

Automation lab

The main need is to enable faster responses to customer requirements. Covid did not only just affect the industry, but rather required a complete transformation in the work methodology, involving faster testing and analysis services and less mobility of people. So, we must be closer to our clients to work due to the travel restrictions imposed by the authorities, allowing them to work locally.

During the pandemic we helped clients to improve their know-how for our technologies, and it is something that will stay implemented forever.

On average, our service team utilization during the pandemic was close to 80%, which represented a full agenda that we accomplished even with the strict Covid protocols.

EMSNOW: Who is using it? How many customers have taken advantage, what were the benefits?

It is difficult to say how many customers have received the benefits from our facilities, since many clients attend in person while others decide to use our tools remotely to start up their plants.

Cleaning lab

Customers are able to NPI, test and simulate the processes without the need of disturb their production schedule.

EMSNOW: What plans do you have for expanding if any? How has it impacted the industry? Where do you see the challenges for electronics manufacturing in Mexico?

Typically, our expansion plans are driven by an industry pull. We will continue to invest in the different regions of Mexico and also in international sales: the US market has shown great growth for us, so we are considering being in two more places, in the east and the west. The future looks very positive for manufacturing electronic products in Mexico.