Creating a Smart Factory with CIM and IoT

By Zac Elliott, Mentor, a Siemens Business

Zak Elliott

To create smart factories capable of autonomous optimization of interconnected processes, it is necessary to integrate the myriad of disparate computer systems for electronics manufacturing. Given the complexity and cost associated with this undertaking, the path to smart factory adoption may seem out of reach to all but the largest manufacturers. Defining a general approach to the smart factory infrastructure is imperative to reduce the complexity, effort, and cost; thus, the electronics assembly industry is rapidly improving automation and analytics to support increased flexibility, lower overhead and quality standards. The Smart Factory and Industry 4.0 initiatives are focused on further integrating manufacturing processes with business processes to autonomously and continuously optimize operations.

Computer Integrated Manufacturing (CIM) systems are critical to any electronics manufacturing operation. Many varied computer systems, automated robots, and technical experts are working together to execute manufacturing and develop streamlined processes, optimize the supply chain, and manage product quality. Linking these processes can be an arduous task requiring a multi-disciplinary team of technical process experts, product engineers, operational resources, and business process owners. Although integration can be a complex and expensive proposition, the ability to share and control information between equipment and business systems enable automated and optimized sophisticated manufacturing processes.

Electronics Manufacturing Effects

Electronic manufacturers are seeking solutions that represent tangible Industry 4.0 and the smart factory progress, namely autonomous, continuous optimization of operations. SMT equipment vendors have been the first to respond to market needs by expanding the scope of their CIM systems beyond controlling individual machines to manage the entire production line or other ancillary processes, such as material management. Partnerships with complimentary equipment vendors also enable entire end-to-end solutions for the market.

There is still significant complexity in connecting the varied business processes needed for most smart factory functions. A given manufacturing site may have multiple SMT platforms and a broad range of third-party equipment platforms to support. Thus, it is advantageous to define a generic smart factory approach to integrate and connect these heterogeneous environments with minimal complexity and cost.

Smart Factory Infrastructure

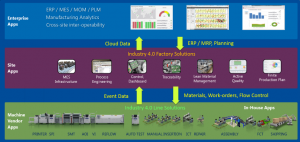

To define a more general infrastructure, the existing CIM applications can be grouped into the three primary layers that exist functionally: process applications, site applications, and enterprise applications. These groups generally serve the same function in relation to each other as shown in Figure 1.

Figure 1: Smart Factory Layers

The lowest layer, Process Applications, control or manage a given manufacturing process. These are machine vendor applications, Programmable Logic Controllers (PLC), sensors, or custom applications which run equipment, collect data, or guide a person or process. Process applications may create event data valuable to other processes or require information from the higher-level infrastructure, such as material information, work orders, and flow control.

Sitting above the process-specific applications are the Site Applications that manage the overall manufacturing flow, such as work order details, and material information required by the process-specific operations. The Manufacturing Execution System (MES) infrastructure, process engineering, quality management, material management, and finite production planning applications are typical site-level functions. These applications consume the event data created by specific processes to actively manage production operation to operation in most cases.

At the top level are the Enterprise Applications that manage higher-level, cross-functional business processes. Some examples of enterprise-level applications are ERP, MES, Manufacturing Operations Management, (MOM), Product Lifecycle Management (PLM), and business analytics. These applications may receive data that is aggregated from the process-specific applications and then summarized by the site level applications. The enterprise applications provide the site level applications with the overall resource, material, and production plans.

With this delineation between the layers of applications in the smart factory, there is then a clear flow of data; business requirements flow down from the Enterprise Applications to the Site Applications. The Site Applications translate the requirements into concrete manufacturing plans which flow down to the Process Applications. The Process Applications gather event data to send back up to the Site Applications. The Site Applications aggregate and summarize the relevant event data to be sent finally up to the Enterprise Applications.

Technical Barriers and Requirements

The integration of disparate automated processes and the computerization of human decision making requires normalized data on which to operate. Normalized data must be expressed in a single language with a consistent meaning regardless of the source of the information.

In the electronics assembly industry, there is currently no standard defining the complex data content required to model manufacturing processes. While various vendors support proprietary interfaces to their own technology, technical expertise is required to map the data content from one technology to another. Existing legacy standards focus on connecting and moving data, but there is no responsibility for the complex data content to the degree necessary for trusted decision-making. As a result, existing integrations and solutions tend to limit focus on a narrow slice of a larger business process, or only function point-to-point between partner vendor solutions or custom integrations.

Emerging IoT Technology

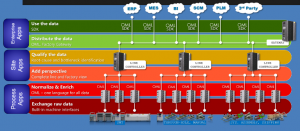

The emergence of the Internet of Things (IoT) in the manufacturing industry offers the capability to connect processes and acquire data, but an infrastructure must be defined to manage the capabilities and distribute the information between multitudes of possible data streams. Considering the three levels of applications discussed previously, and assuming a single language as proposed, a general approach to connecting the factory can be defined by the responsibilities of each layer of applications as shown in Figure 2.

Figure 2: Smart Layer Responsibilities

Process Applications will be responsible for exchanging raw data with equipment and operators and will normalize the events and information into a single language for consumption externally. Internally, each application can function optimally for the given equipment or process, and will expose the same generic interface to describe the manufacturing operations being performed.

Site Applications will be responsible for adding perspective from the complete line and qualifying the data collected to identify root cause and bottlenecks. Since the Process Applications all produce the same type of normalized events in a single language, there is minimal effort required to connect processes for the highest level of detail and perspective.

Enterprise Applications will be responsible for distributing the information from the underlying infrastructure for external use. In addition to the existing enterprise-level resources (ERP and MES), a gateway to the IoT manufacturing infrastructure provides the resources in the factory and the events supported by the resources.

With this infrastructure, individual manufacturing processes can easily share information and control, and the entire manufacturing flow is exposed for external interface. Smart applications can begin connecting the individual manufacturing operations with business processes to optimize the production flow. Some example applications of this infrastructure are discussed further.

Factory Intelligence Application

With a mix of different customers, products, factories, lines, and machines, there may be hundreds of different key performance indicators (KPIs) to consider. Some of these measurements may require data from multiple processes, for example Overall Equipment Effectiveness (OEE) calculations, providing the performance of factory resources and the quality of the products produced.

A bottleneck is caused by some external force that is not being measured. A machine may not be operating because of an actual malfunction in the equipment, or it may be waiting for some upstream or downstream process. Perhaps the operator is on break, or there is a shortage of materials causing the downtime. Such external forces must be considered to identify the root cause of a problem and provide for an actionable response.

A site-level factory intelligence application must consider information from the both the Enterprise Applications and the Process Applications. First, the process-specific applications would provide performance data regarding the status of the equipment being managed. Next, the site based constraints will be used to qualify any process status based on constraints such as the overall factory schedule, material availability, or the upstream/downstream bottleneck.

With information about process performance and the constraints influencing production, many optimization opportunities are possible. The process-specific layer can be optimized based on external knowledge from other processes and higher-level applications, while the Site Application layer benefits from detailed process information from each individual equipment.

Closed Loop Feedback Application

A smart application example is in closed-loop feedback where measurements taken at one process are used to automatically adjust the operation of another process to maintain a consistent result. For example, the SMT machine could make adjustments to placements based on drift data being measured at automated optical inspection (AOI)

A site-level analysis application would need to collect the placement and material information from the SMT machine through the process-specific application managing that equipment. Next, the real-time measurement results from the AOI will need to be collected and analyzed to identify a process control problem. The results of this statistical analysis can then be fed back to the SMT machine so that adjustments and compensations can be made as appropriate for the equipment.

Since a normalized interface is used at the AOI and the SMT machine, this application would function across varying platforms while allowing each individual equipment to take the optimal action for its technology.

Finite Planning Application

The finite planning of the SMT schedule represents a significant opportunity to improve and optimize through automation and computerization. In a traditional situation, the Enterprise Resource Planning (ERP) system manages the customer demand and material requirements in very coarse granularity with little detail of the resources used in manufacturing. Once the work order demand is generated in the ERP system, much diligent work is put into developing a production plan to satisfy the orders. Complicated spreadsheets and workbooks are used to model the manufacturing flow and to manage constraints that are external to the ERP system. Unexpected changes in the customer demand or the manufacturing constraints are difficult to integrate into the existing plan. Optimization of product groupings happens infrequently outside of the day-to-day planning activity.

Conversely, using a smart factory topology defined above, the automation of the finite planning process would function at each layer of the factory. At the enterprise layer, the ERP system will manage the customer requirements and the high-level site calendar. At the site layer, a digital model of the production process needs to be generated based on all of the constraints in the factory. All of lines, machines, processes, materials, transactions, and resources must be taken into account in the model to create a simulation of the manufacturing process. The process-specific layer must perform two important functions. First, it must supply real-time performance information from the manufacturing equipment through the IoT infrastructure. Second, it must supply the means to simulate production for the given process.

When all layers are working together, a fully optimized production plan can be developed. Demand from the ERP system is deconstructed into the individual manufacturing processes. Iterative simulations find the ideal manufacturing sequence using the static site constraints and the live performance data from the factory. A feedback mechanism between the planning application and the equipment processes provides optimized programs and product groups based on the discrete demand. Changes in the demand or the constraints can be continuously accounted for in the production schedule.

Lean Material Management Application

For many manufacturers of electronic assemblies, maintaining an efficient supply chain is key to success. Significant investments in ERP systems and automation ensure that there are materials in the warehouse to satisfy the customer demand. With rich, detailed information available in the Smart Factory, a lean material engine can bridge the gap between the ERP inventory and the shop floor to provide just-in-time (JIT) material logistics to the machines.

The first step to lean material management is accessing information held in various systems. The ERP system will provide the work order demand which defines the sequence and schedule of products to run. The warehouse management system provides the detail of individual components available for production. At the process specific layer, the equipment system will provide the machine program information, performance information, and material consumption details.

Next, using production schedule, the current machine setup, and the live IoT data stream from the equipment, the lean material engine can determine when individual components will need to be replenished; either on the current order as reels are exhausted, or on an upcoming order during a changeover. With the connection to warehouse management, the lean material engine can determine the ideal location from which to move components and automatically initiate the movement transactions. The consumption data reported by the individual machines can be aggregated and extremely accurate reports made to the ERP system.

Finally, the large line-side buffer stocks are unnecessary. Material is ordered from the warehouse or from Kanban storage only when needed on the machine; with automated reporting of consumption and wasted materials from the machine, the ERP inventory is as accurate as possible.

Traceability Application

Traceability data collection has traditionally been a difficult requirement for manufacturers. The complexity and cost associated with collecting detailed, accurate data could lead to inconsistent results as individual traceability requirements are negotiated between the customer and supplier on a product-by-product basis.

To improve the effectiveness and consistency of traceability data collection, the IPC-1782 standard was developed to define a clear, industry-wide specification for traceability. This standard features several levels of traceability based on the risk involved in the product or process. The individual traceability levels vary in the detail and accuracy of the data being collected. At the lowest level, summarized data is collected manually by operators, and at the highest level, comprehensive data must be collected primarily from automated equipment.

When taken as part of the smart factory, the requirements for traceability data collection can be fulfilled by the existing process applications in the smart factory infrastructure. Since the process applications support a neutralized language and a normalized set of events, consistent information can be aggregated by the site layer applications regardless of the particular machine platform. This supports the need for detailed and consistent data regardless of the equipment platform.

Using the IPC-1782 standard format, the summarized traceability information aggregated by the site application layer can be transferred to the enterprise applications and externally to the relevant customer. Connecting the three layers of smart solutions through vendor-neutralized, standard formats reduces the complexity required to implement a meaningful traceability solution.

In conclusion, many opportunities exist today to implement improvements based on automation of manufacturing and business processes using the smart factory infrastructure. With this approach, machine vendor solutions are enhanced through the exchange of information with other machines and site applications. By collecting data from all manufacturing processes—historically troublesome requirements such as traceability—become easier to fulfil. This leads the industry to a greater adoption of smart manufacturing functionality.

Author Bio:

Zac Elliott is a Technical Marketing Engineer with Mentor, A Siemens Business. Working directly with electronic manufacturing service providers in the medical, aerospace, automotive, and public-safety markets, Zac ensures that key requirement for the Smart Factory are fulfilled using software and automation. Before joining Mentor, he was responsible for developing and implementing solutions for a global contract electronics manufacturer, providing an in-depth understanding of the market pressures driving Industry 4.0. Recently, Zac has served as a member of the IPC task group working on an industry standard for traceability of critical electronic components.