Clean soldering systems with pyrolysis technology from Rehm

Rehm’s efficient new residue management system increases availability and lengthens maintenance cycles

As with many other thermal processes, the soldering of electronic assemblies creates solder fumes, aerosols and solid particles (residues) that need to be removed from the process cycle. With the VisionXP+, Rehm Thermal Systems has established an effective residue management system for reflow convection soldering. The continuing development of this in collaboration with customers and experience gained from over 2000 installed systems demonstrate that thermal pyrolysis is a reliable method for cleaning the process gas and reducing maintenance costs.

VisionXP+ system

Without an effective residue separation system, the concentration of volatile organic compounds in the process atmosphere would increase steadily, this entailing a high risk of contamination together with a high level of maintenance and repair activity. The VisionX series from Rehm Thermal Systems has featured two trusted residue management systems for many years: pyrolysis in the heating zones plus cold condensation and filtering in the cooling line. This ensures that residues in all states – gaseous, liquid, crystalline and particles – are removed from the process gas, effectively and economically in energy terms.

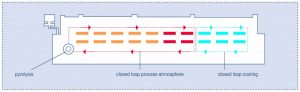

In the VisionXS and VisionXP+ models, residue management functions via a combination of pyrolysis from the inflow to the peak zone plus cold condensation in the cooling line. In the pyrolysis process, long-chain molecule compounds in the solder fumes are broken down (cracked) into short-chain molecules by thermal splitting when heated (450 – 900°C). After cracking they are small enough to be deposited in the granulate and removed from the process.

The principle of cold condensation has also proven effective for gas cleaning in reflow soldering technology. It is used in all VisionX series systems – either complementing the pyrolysis in the case of the VisionXP+ or responsible for the entire residue management, as with the VisionXC. The process gas is fed through a multi-stage cooler-filter system in a closed loop, so that the residues can condense in the cooler while particles and droplets are deposited in the filter. The cleaned gas is then fed back into the process.

Schematic illustration of the VisionXP+ with pyrolysis in the infeed zone

This effective residue management system with its two principles of functioning cleans the process gas thoroughly and reliably. The result: top soldering quality, minimal downtimes and a long service life for your Rehm equipment.

About Rehm Thermal Systems

Rehm is a technology and innovation leader in the state-of-the-art, cost-effective manufacturing of electronic assembly groups and specialises in thermal system solutions for the electronics and photovoltaics industry. Rehm is a globally active manufacturer of reflow soldering systems using convection, condensation or vacuum, drying and coating systems, functional test systems, equipment for the metallisation of solar cells and numerous customised systems. We have a presence in all key growth markets and, as a partner with almost 30 years of industry experience, we are able to implement innovative production solutions that set new standards.