Catalyzing Change: Sustainability and Green Initiatives from High-quality OEMs for Electronics Manufacturers

In the realm of PCBA manufacturing, a significant transformation is underway, with sustainability and green initiatives at the forefront. Investors, customers, and employees are demanding that companies commit to better ESG (environment, social, governance) solutions overall. And with the electronics industry accounting for 4% of global greenhouse gases, electronics manufacturers are under significant pressure to adapt and improve. However, the path to sustainability is full of challenges, and traditional ways of thinking are insufficient.

Electronics manufacturers are exploring ways to optimize performance, aiming to extract every ounce of efficiency from equipment and materials. This drive towards efficiency is not solely motivated by sustainability imperatives but also by the need to meet surging market demands without the prohibitive outlay of capital for new equipment.

Navigating the Complex Factors of Sustainability and Profitability

Investing in new equipment presents a resource-intensive dilemma, both in terms of financial burden and environmental consequences. The upfront costs are obvious, but there’s also the less conspicuous increase in carbon footprint associated with buying and operating new machines. The current global economic landscape, marked by inflationary pressures, further exacerbates the problem. The skyrocketing costs of goods compel manufacturers to safeguard already thin profit margins, forcing them to maximize output from existing resources.

As if these challenges weren’t enough, the surge in energy and construction costs further complicates the equation, making the once straightforward decision to add equipment a complex and long-term cost consideration, given the recent dramatic cost increases over the past year. In this evolving landscape, manufacturers face the dual challenge of achieving sustainability and profitability while navigating the intricate interplay of seemingly uncontrollable factors.

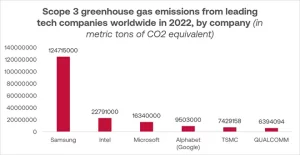

Laricchia, F. (2023) Scope 3 GHG emissions: Top 10 global tech companies 2022, Statista. Available at: https://www.statista.com/statistics/1250484/greenhouse-gas-emissions-scope-3-top-tech-companies-worldwide/ (Accessed: 29 November 2023).

| Scope 1 | Scope 2 | Scope 3 |

|---|---|---|

| Scope 1 is for direct emissions that are released into the atmosphere as a direct results of company activities, and includes emissions from stationary combustion (fuels and heating sources), mobile combustion (burning fuel for cars, trucks, etc.), fugitive emissions related to greenhouse gases (refrigeration, A/C), and process emissions related to manufacturing processes (factory fumes, chemicals, etc.). | Scope 2 includes indirect emissions from purchased energy (electricity, steam, heat, cooling). | Scope 3 includes all indirect emissions (not covered in scope 2) linked to the company’s operations and covers 15 different categories in both downstream and upstream processes. Downstream emissions include end-of-life product waste and investment costs. Upstream emissions cover a wide range of activities including all travel, distribution and transportation, as well as material waste. This is the most difficult scope to both calculate and improve and is currently not required for reporting. |

Unveiling Operational Insights for PCBA Manufacturers

More and more, OEMs are requiring their supply chain to improve their sustainability initiatives – automotive companies like Stellantis and General Motors are requiring suppliers to improve all efforts related to carbon neutrality, social programs, and sustainable procurement practices. In turn, many downstream suppliers, including electronics manufacturers, are turning to software to fulfill these new requirements.

Among others, Cogiscan’s analytics platform offers manufacturers a comprehensive tool to accurately assess and visualize manufacturer’s global OEE. This includes in-depth insights into critical performance metrics such as Cycle Time, Throughput, and machine-to-line-to-factory-level performance. Cogiscan’s analytics system goes a step further by investigating the root cause when deviations occur, providing drill-down analyses that shed light on the reasons behind such issues. With Cogiscan, you gain not only the ability to measure efficiency, but also the knowledge to address and rectify operational discrepancies quickly and accurately, before they adversely impact productivity.

Put succinctly, Factory Intelligence platform will help facilitate the maximization of the factory’s current infrastructure’s utilization. By enhancing efficiency, you’ll avoid the need for additional machines or production lines, thereby making the most of your current resources and investments.

Additionally, the Cogiscan platform is built on track, trace & control – providing real-time visibility into all facets of manufacturing processes and operations. This foundation provides manufacturers visibility into all resources in use on the factory floor, enabling better control over all facets of the manufacturing environment more effectively.

Again, mere performance visualization falls short of addressing the specific needs of PCBA manufacturers. What’s essential is the capability to comprehensively analyze WHY operational issues occur and using TOOLS to enable root causes analyses to drive corrective actions when necessary, and in some cases to prevent errors from happening in the first place using poke yoke solutions.

Collaborative Partnerships for Long-Term Success in PCBA Production

Some OEMs are taking their manufacturing partnerships to a whole new level by going as far as investing in software installations at their Contract Manufacturers (CMs). This shared commitment to ensuring the long-term success of their chosen CM isn’t just about strengthening the supply chain; it’s about building a lasting, cooperative partnership to keep products rolling off the production line smoothly.

In the past, OEM producing high-reliability products placed strict requirements on their CMs to implement complete and robust traceability systems. The impact of ESG policies means new requirements to implement appropriate systems to measure, report and improve efficiency metrics. OEMs require consistent KPIs to benchmark different sites and with a few different CMs, this can be a daunting undertaking unless they are utilizing the same analytics tool.

Green Initiatives Beyond the Assembly Line

It’s important to acknowledge that meeting sustainability requirements in today’s manufacturing landscape extends far beyond the capabilities of software in general. Initiatives such as recycling, transitioning to renewable energy sources for powering manufacturing facilities, and reducing the overall logistics and shipping footprint are indeed crucial components of a comprehensive sustainability strategy.

However, the primary focus of this piece is to delve into how manufacturing software can dramatically help OEMs and EMS providers with optimizing their current processes within the factory. Cogiscan specifically specializes in the meticulous analysis, optimization, and control of production operations within existing infrastructure, empowering electronics manufacturers to enhance efficiency and achieve operational excellence from the inside.