Game Changers – AI Enabled Machine Vision Inspection

By Philip Stoten, writer, podcaster and speaker on all things manufacturing

When we’re not talking about AI in manufacturing, we’re talking about automation, sometimes to ensure more consistent quality or traceability, other times to ensure we can be competitive enough to reshore manufacturing and make supply chains more agile and secure. Whichever way you look at it the automation of inspection through machine vision and the application of AI is a game changer on so many levels.

Let’s unpack some of the many reasons not using machine vision and AI is risky at best, catastrophic at worst, starting with quality performance

By Philip Spagnoli Stoten Founder of SCOOP

Starting with the straightforward issue of quality assurance and quality control, it is clear that what has been done in the past is insufficient, inaccurate and unreliable, often with disastrous results. Whilst the human eye and the human brain are fundamentally impressive and amazing, they do not provide the consistency, accuracy or efficiency we need for modern manufacturing.

When quality assurance fails in the construction of a car or an airplane, the results are expensive and damaging to the brand at best, and fatal at worst. According to National Highway Traffic Safety Association (NHTSA) there were over 30 million vehicles recalled in the USA in 2023 alone. And in recent years we’ve seen numerous high profile examples of how quality issues can cause disastrous failure in the field. The impact of these failures can be as extreme as loss of life, but cover the full spectrum of brand and reputational damage, costly recalls, expensive rework and much more.

To ensure quality, manufacturers need to automate inspection in a way that does not rely on human inspection, but instead uses quality images, with complete product coverage, captured automatically throughout the manufacturing and assembly process. This could, and should, result in zero escapes, complete inspection coverage, all at the speed of the line and with lower cost. Add to this that the process is digitally native, and hence paperless, delivering 100% surgical traceability that will minimize any potential recall costs.

Beyond quality is the issue of automation

Automation may be as much a buzzword as AI in manufacturing right now, but this is not without reason, and needs to be considered within other global trends. Right now we are seeing the pendulum swing from globalized supply chains to more regional solutions. This is happening for numerous reasons – trade wars, supply chain fragility highlighted by the pandemic, component shortages, geopolitical friction, anti China sentiment, logistics challenges, and the straightforward desire to manufacture ‘at home’ or at least closer to consumption. Regardless of the reasons, we are seeing a manufacturing renaissance in places like North America and Western Europe, where wages are higher and talent is scarcer!

The only way these demands can be met is to use automation to increase competitiveness and reduce the need for talent that is simply not available. The alternative is the slowing, and even stalling, of any manufacturing renaissance we are seeing, and a return to longer, less sustainable and less robust global supply chains. To compete on the global stage, North America, and any other geography, must be able to provide reliable, high quality manufacturing at competitive prices. And that means the intelligent application of automation, especially in areas like quality inspection and assembly verification where talent is hard to find, hard to train, expensive, and perhaps not as reliable as we really need it to be.

Shining examples of innovation alongside domain expertise

There are numerous examples of innovation and AI being used in this area, but the companies that I believe will succeed all have something in common, the combination of a creative understanding of machine vision and the application of AI, with a deep domain understanding of manufacturing.

Look at what Loopr.ai and their customers are doing in the area of visual inspection software to improve the efficiency of visual inspections, address workforce challenges, and ultimately reduce the cost of quality while improving manufacturing performance. They are already working with major brands like Boeing, Daimler Truck and Sandvik, and whilst the aerospace and automotive industries seem like a great fit, their solution is clearly valuable in any manufacturing environment.

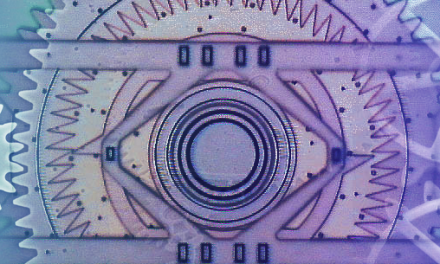

Another good example is Instrumental, a company that is more focussed on electronics manufacturing and delivers an AI and data platform for the entire product lifecycle. They too are working with an impressive list of brands including Meta, ChargePoint, Lenovo and Motorola. They have worked with seven of the top ten global EMS companies and have an impressive list of manufacturing, technology and imaging partners.

What is exciting, and I think extremely important, is that both of these companies have been founded by individuals that worked in manufacturing and identified specific problems that they are now solving. Both founders, Priyansha Bagaria of Loopr and Anna-Katrina Shedletsky of Instrumental, are manufacturing experts at heart and, with their teams, have applied machine vision and AI is a creative way to solve real manufacturing challenges.

Implementing Machine Vision AI is not just about keeping up with a new trend in manufacturing but is something that can help with long term success, drive better quality, reduce failures, increase productivity and so much more.

Learn more about both of these companies at Loopr.ai and Instrumental.