Illuminating the Path: The Crucial Role of Traceability in Modern Electronics Manufacturing

In the sprawling landscape of modern electronics manufacturing, the manufacturing process can be likened to an enigmatic labyrinth, where a PCBA’s journey, from conception to the finished product is an intricate web of supply chains and assembly requirements. Within this dynamic and fast-paced reality, the importance of traceability should be looked at as a guiding beacon, an illumination to the best path forward.

Traceability in electronics manufacturing serves as a fundamental pillar that fosters product integrity, safety, compliance, and supply chain efficiency. As the industry continues to evolve, embracing traceability not only drives business success but also demonstrates a commitment to responsible and sustainable manufacturing practices.

IPC-1782 and the 4 levels of Traceability in Electronics

Since 2016, the IPC has promoted traceability in our industry through the standard IPC-1782 – Standard for Manufacturing and Supply Chain Traceability of Electronic Products (now IPC-1782A). Focusing solely on traceability, this standard can be looked at in parallel with other industry-specific standards such as AS9100, IATF 16949 (ISO/TS 16949) or ISO 13485. The IPC divides traceability in 4 different levels:

- Level 1 Traceability: Basic

- Level 2 Traceability: Standard

- Level 3 Traceability: Advanced

- Level 4 Traceability: Comprehensive

Each level has specific requirements and IPC even provides recommendations for products based on the PCBA’s IPC Product Class. If we refer to their Quick Reference Table for the standard, the range of traceability goes from “Listed to work-order by part number and incoming order + Significant process exceptions against batch record/traveler” to “Exact materials used on each PCB + Capture all available metrics including test results and process data”.

As Level 1 Traceability requires as little as 90% manual data collection and a reporting lead time of 48 hours, most factories can adhere to this standard, and is enough for many electronics manufacturers. However, industry regulations continue to become more and more stringent every year, and many modern manufacturers are looking to achieve level 3 or level 4 traceability.

Please note that each specific product will require its own assessment in order to define which level of traceability is required based on a number of factors. As higher levels of traceability require at least 90% automated data collection, meeting this requirement will depend on the type and amount of information you can collect from the machines and stations in your factory. Since your traceability reporting will only be as good as the data in them, you need to evaluate your connectivity and ensure access to the trove of data awaiting on your factory floor. Connectivity is the foundation of any traceability, or other digitalization, project especially when real-time data is needed. Check out our connectivity solutions if that is something you’re currently struggling with.

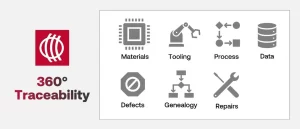

Cogiscan’s 360° Traceability Solution

As mentioned, our solutions are suitable for any level of traceability as defined by IPC. A lot of manufacturers use our software for levels 2 and 3 traceability, but some of our customers are also using our software to achieve level 4 as well. Again, having the right software is one thing, but implementing the right process is equally important. Nevertheless, our 360° Traceability solution offers complete and accurate tracking and reporting of the entire production process, including:

- Materials

- Tooling

- Processes

- Data

- Defects

- Genealogy

- Repairs

As a holistic traceability solution design specifically for the PCBA industry, our solution automatically captures and stores the complete build history of all manufactured units. Embedded in Schneider Electric Cavite manufacturing process for more than 10 years: “Cogiscan has been a part of our system for 10 years and brought back a lot of benefits in terms of Traceability and Quality Control in our PCBA. Its real-time capability is a turnkey of Schneider Cavite, a pioneer in Smart PCBA Manufacturing in the Philippines.” – and they’re still using it today.

Cogiscan’s Traceability Software & IPC-1782

| Product | Materials/Tooling | Processes |

|---|---|---|

| Product & work order info | Components | Program & Recipe Name |

| Operation’s start/end date/time | Consumables | Temperature Setting |

| Line ID | Fixtures | Actual Temperature |

| Machines ID | Tooling | Test Pass/Fail w. Defect code |

| Workstation ID | Unique ID | Inspection Pass/Fail |

| Operator Name | Part Number | Measured values for electrical |

| Operator ID | Supplier | |

| Lot & Dates codes | ||

| MSD Information | ||

| Reference Designator |