How to Avoid Getting Stuck with a SMT Manufacturing Analytics Tool Filled with Meaningless Data

In today’s world, many software companies, and even some of the leading machine vendors, offer interesting manufacturing analytics tool for the PCBA industry. Facing one of the biggest component shortages ever, these dashboards have only increased in popularity as electronics manufacturers hope to utilize and maximize all resources, included machines and materials, to the fullest extent.

Lately, we’ve heard from hundreds of different factories all over the globe with the same kind of problem – they have the latest visually appealing analytics dashboards, but they’re still struggling to access the right data to calculate their KPIs…

We’ve all heard that before: “Garbage In, Garbage Out”.

Let’s say you want to quickly identify your current asset utilization or which one of your lines is dealing with the worst downtime metric. This might seem like a simple task, but for those of us in electronics manufacturing, we understand it’s actually trickier than one might think. Yes, your AOI and your pick and place machine will probably give you the data you need for this, but what about your other machines? Are they giving you the data you need? And if so, in what format? Because it is one thing to have access to the machines’ data, but it’s a whole different story if you need to feed this data in a specific format, in a single place – like your newest SMT manufacturing analytics dashboard, for example.

No Widely Adopted Standard for SMT Machine Communication

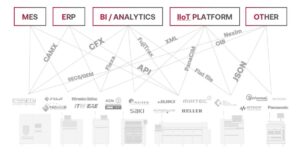

As you’re probably painfully aware, there is no widely adopted standard for machine communication across the various brands and models of electronics assembly equipment. Therefore, your placement machine might feed data in a proprietary protocol, your AOI in CFX format, and your SPI in CAMX, and with your reflow oven exporting in XML.

As you’re probably painfully aware, there is no widely adopted standard for machine communication across the various brands and models of electronics assembly equipment. Therefore, your placement machine might feed data in a proprietary protocol, your AOI in CFX format, and your SPI in CAMX, and with your reflow oven exporting in XML.How to Harmonize and Standardize Multiple SMT Data Formats?

ARC Advisory Group [the world’s leading industry tech advisory group in the industrial space] recommends that manufacturers, machine builders, system integrators, and suppliers to machine builders use a third-party solution to speed up implementation, which will lower the total cost and speed up the time-line of providing connectivity.

What is a “third-party solution” when it comes to SMT machine connectivity? It’s a software that is created by a vendor to be compatible with the products of another vendor. Our industry’s most popular machine connectivity choice is Cogiscan’s Co-NECT, a vendor-neutral platform that includes a large library of plug-and-play software interfaces for each brand and model of equipment.

What is a “third-party solution” when it comes to SMT machine connectivity? It’s a software that is created by a vendor to be compatible with the products of another vendor. Our industry’s most popular machine connectivity choice is Cogiscan’s Co-NECT, a vendor-neutral platform that includes a large library of plug-and-play software interfaces for each brand and model of equipment.