Seeking Validation: Over-the-Air 5G Testing

SOURCE

By Dr. Lin Lin, Chief System Architect, Jabil Wireless

As wireless companies, technology startups and cellular service providers invest tens of billions of dollars into the 5G network, the next generation of connectivity is finally on its way. Just as 5G itself is still being explored and developed, so too are the processes supporting it — like over-the-air 5G testing — that will enable the broader world to enjoy its high speeds, low latencies and huge numbers of connections.

Lin Lin, PhD

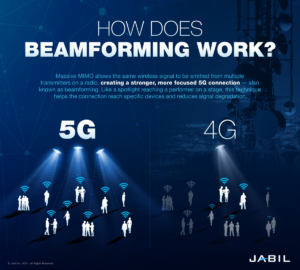

The technology is divided into three spectrum bands, with the most innovative and in-demand 5G spectrum being its top-tier high-band, or millimeter wave (mmWave). The high-band spectrum will enable the lightning-fast 5G speeds expected to open the door to new applications (or the “killer app”) for wireless connectivity. Though mmWave has a short wavelength and is geographically limited to urban regions or areas close to a radio, it can deliver multiple gigabit data rates to end users. 5G network connections, especially in the higher millimeter wave frequencies, use the antenna technology massive multiple input, multiple output (MIMO).

Massive MIMO uses multiple transceivers on one radio to form one or several beams between the base station and the user equipment (UE) — like a smartphone or other IoT device. At mmWave’s frequencies (24 to 42 GHz), signal tends to be absorbed into the air quickly, so massive MIMO is used to overcome the high signal loss. Beamforming, where multiple transmitters emit the same signal to create a longer, stronger, more focused beam, is also made possible through massive MIMO. One beam can cover multiple UEs, and spectrum can be reused among beams.

One of the most important steps in making 5G a reality is testing. Before a brand-new wireless technology is launched to consumers and businesses, its performance must be validated through rigorous tests that recreate typical conditions the radiofrequency will encounter in the real world.

However, the more complex the wireless technology, the more complex the testing. In 4G and 4G LTE performance testing, radios could be connected to test equipment via cables, with two or four transmitters sending signals to two or four receivers. For a number of reasons, a different type of validation is required for 5G millimeter wave. First, consider the physics of mmWave; the signal is propagated and delivered through the air. Next, it would be virtually impossible to test hundreds of transceiver and receiver pairs via cable. Then, on mmWave base station radios, the transceivers and antenna are integrated on one board and densely packed together, so there is not even a place to connect the test cables.

What is 5G Over-the-Air Testing?

In order to validate the ability of the 5G radio’s transceivers, or antenna elements, to form beams (beamforming) and steer them (beam steering), designers perform over-the-air tests. During these tests, they can measure the beam patterns in 2D and 3D to find their width, side lobe levels, null depths and symmetry, none of which can be done with previous-generation tests that used cables.

All new 5G devices must meet the new specifications laid out by the 3GPP before commercialization. Over-the-air testing methods are necessary to check those boxes, including:

- Radiofrequency performance (signal strength)

- Demodulation (data throughput)

- Radio resource management

- Calibration and validation of manufacturing

Part of the new 5G New Radio (or 5G NR) standard, mmWave falls into Frequency Range 2 (FR2), which is more challenging to test than the frequency in Frequency Range 1 (FR1). FR1 frequencies are similar to those of 4G LTE, which can be tested over the air or via cable. However, testing 4G LTE devices over the air is simpler than testing 5G NR F2 devices, as the former is typically used in MIMO mode, not beamforming mode — a simpler OTA test that involves primarily the spatial relationship between the radio and the device receiving the signal, such as a smartphone. The 5G NR F2 test analyzes the power angular spectrum similarity percentage (PSP), or as a way to verify the UE’s MIMO performance.

OTA tests can happen in the near field (within a few wavelengths of the antenna beam) or the far field (known as the Fraunhofer distance, calculated as 2D2/λ). The far field is how users will encounter 5G in the real world, when the radio signal is beamed from a tower or small cell to a smartphone or IoT device. But as I’ll explain, the most accurate far-field testing typically requires an amount of space that is hard to come by in the manufacturing setting.

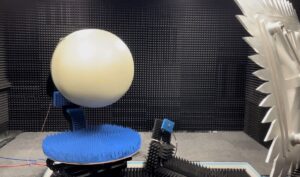

The OTA testing system contains four main parts: a positioner holding the device under test (DUT), one or several antenna probes placed at far field from the DUT, a measurement instrument connected to the probes to generate/receive radiofrequency (RF) signals, and an anechoic chamber. This chamber is lined with non-reflective, absorbent material inside, with shielding on the exterior, to keep outside interferences from influencing the test.

The device under testing (DUT) inside Jabil’s 5G over-the-air test chamber.

The goal of OTA testing is to measure a DUT’s RF performance accurately, as if it is connected to the measurement instrument through a perfect channel in the far field. Any degradation of DUT RF performance is attributed to its design or manufacturing defects. Establishing such a “clean” OTA test system is no easy task in engineering labs, and it is particularly difficult in a high-volume production environment like a factory.

The Challenges of 5G Over-the-Air Testing

As a technology that will enable day-to-day communication, help businesses run and potentially power life-saving digital healthcare devices, the performance of 5G radios must be dependable and reproducible from the factory floor to the cell tower.

One of designers’ and engineers’ biggest challenges is ensuring consistency in both the manufacturing and testing of these radios is that they must be produced and must perform identically. Designing for manufacturing and testing radio designs early — before manufacturing begins — can help prevent surprises when it’s time to validate your new 5G radios.

For a typical mmWave base station radio, its far-field distance is considered anything further than 8 meters. Construction of a chamber large enough to accommodate OTA across this distance in a factory is costly. Reflector-based Compact Antenna Test Range (CATR), which would allow the radio to be tested at a shorter distance, is also expensive and difficult to install. Additionally, these direct and indirect far-field chambers require someone to walk in and hang the DUT on a positioner for each test. This is not a very efficient system when hundreds or thousands of radios are being manufactured and tested each week.

Finally, outside of the factory setting, radios will experience a range of temperatures and climates depending on the location it’s installed. Radio behaviors change when subjected to different temperatures, so merely testing in a climate-controlled environment does not provide an accurate picture of how it will behave in real-world use.

Faced with all of these challenges, wireless OEMs developing 5G technology might ultimately come to one question: How do you test a radiating 5G antenna combined with a radio while also controlling its environment? Here at Jabil, the answer was to develop our own testing solution.

One-of-a-Kind 5G OTA Temperature Testing

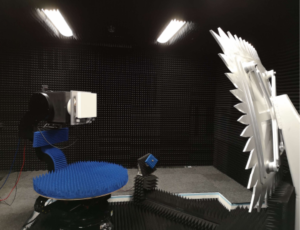

When our team at Jabil set out to develop our own over-the-air 5G test equipment, addressing the temperature question was critical. A 5G radio might end up sitting in the blazing Las Vegas, Nevada, sun or in the frigid air of Helsinki, Finland. To ensure the device works the exact same way in both, we developed a design verification test (DVT) chamber that tests mmWave radios at temperatures ranging from -40°C (-40°F) to 70°C (158°F). This is a first-of-its-kind temperature test solution for 5G base station equipment available for use by industry OEMs before designs reach manufacturing.

The thermal cover covers the DUT and creates a real-world temperature setting inside the test chamber.

The innovations didn’t stop there. We’ve also developed a smaller-than-average production verification test (PVT) chamber that is just 2 meters high, a half-meter wide and 1 meter deep. This chamber was designed to be user friendly and much more time-efficient than existing OTA testing chambers. It contains a drawer on one side, where operators can insert the radio, press two buttons and begin the test. Created with the mindset of safety first, two hands are required to close the drawer and press the start buttons.

Addressing another significant challenge in 5G OTA testing, we are in the process of patenting a more accurate solution to calculating far-field performance based on near-field performance without the need to take the test out of the manufacturing facility. OEMs don’t have time nor space in their facility to test radios in multiple locations, so this solution will help improve radio performance without the need to expend more resources on additional validation. Our team at Jabil is also in the process of extending our OTA solution to cover vehicle radar tests for the automotive industry.

As the potential of 5G has grown, the technologies that underpin and enable it have evolved in order to keep up. From 5G radio and device development to OTA validation, Jabil will keep innovating to bring these new ideas to life.

Over-the-Air Testing is the Final Piece of the Puzzle for 5G Radio Development

For 5G mmWave radios, over-the-air testing is the final stop on the journey to commercialization; there is no other way to validate their design and performance. Testing radio designs before production in the most realistic, yet controlled, space possible helps OEMs minimize waste and get the radios to market quickly to take advantage of the growing opportunities within 5G. Designing for manufacturing and testing, coupled with proactive OTA validation, will iron out potential challenges before production lines start rolling.

As 5G deployment picks up speed in the coming years, over-the-air testing will only be in greater demand. Cutting-edge mmWave testing capabilities are a key component in unlocking the era of 5G. Is your company ready to get connected?