Mitigating the risks of the global chip shortage

By Ivanna Savchuk, Digital Marketing Lead, Microart Services Inc.

This situation is a result of a few unfortunate circumstances. First and foremost, the pandemic has forced the world to live a more digital life which has increased demand for consumer electronics. On top of that, in 2020, some factories in Japan, China, and the U.S. have been hurt by natural disasters, while the US-China political frictions have been providing additional friction.

And it seems like there is little or no light at the end of the tunnel. According to Mintel, some analysts predict the chip shortage will last through until the end of 2022. Others estimate that supply won’t catch demand until 2023-2024.

There are also no quick fixes to the crisis. Even though building of new fabs is already underway, it’ll take years and billion-dollar investments. Some vendors attempt to solve the problem by becoming chip manufacturers themselves. The Wall Street Journal reports that Intel Corp. is considering buying GlobalFoundries Inc.

Mitigating the risks of the global chip shortage

At Microart, we recognise that we cannot solve the global chip shortage. However, at the end of the day, all we really care about is getting things made for our customers, even in times of crisis. This is what saw our customers through the pandemic and this is what will see them through this crisis.

What’s been working for us so far is a combination of approaches, including but not limited to dual sourcing, better inventory planning, and stronger relationships with our trusted suppliers. Regardless of the complexity of the problem, the greatest tool in our risk management toolkit has always been transparency — with our customers, our suppliers, and our partners.

“Our factory is our customers’ factory. We always encourage our customers to work beside us, talk to us as if we were their production team, and don’t hide anything. That’s the added value we provide,” says Charles Tonna, the Executive Vice President at Microart Services.

Counterfeit Boom

As it usually happens during challenging times, there are bad actors that try to take advantage. The semiconductor chips shortage and supply chain issues have created fertile soil for fraudulent suppliers. Because manufacturers are now even more dependent on their supply chains and have little choice but to explore new sources, fake suppliers are coming to the fore, luring manufacturers looking for scarce parts and selling counterfeit or substandard parts and materials. It’s now even more important for OEMs and their manufacturing partners to buckle up and maintain strict counterfeit detection and prevention measures.

Microart’s Counterfeit Policy

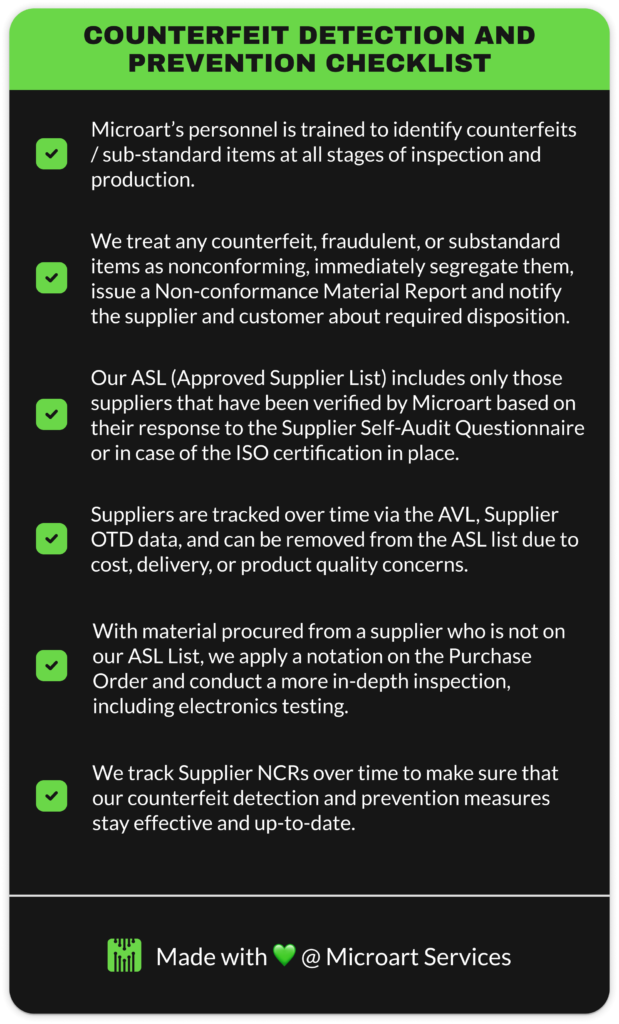

At Microart, we leave no room for compromises when it comes to identifying fraudulent or sub-par items. We have strict counterfeit detection and prevention guidelines in place and have already developed a gut instinct for this type of issue thanks to years of experience. Here are some of the tips that we diligently follow and our Counterfeit Detection and Prevention Checklist.

Each of Microart’s employees knows these guidelines.

“There are suppliers that we consider reliable and others that perhaps require a more diligent approach. Inspection is essential, X-ray machines can reveal if the inside of a chip is empty and we use visual inspection to review how different elements are printed on the components, as well as the packaging.

If we cannot procure an item from the suppliers on our ASL (Approved Supplier List), and we end up buying it from a broker, a customer will need to approve it. For such orders, our engineers always conduct an additional electronic inspection,” says Gord Taws, a Technical Buyer at Microart Services.

Overall, no matter what happens, we want our customers to be confident in each part that goes into their products, as this is the only way to maintain production and close long-term collaboration.