EMSNOW Technology Review: PowerArena computer vision solution for assembly lines

The EMS industry has a habit of reinventing itself on a regular basis, applying technology and process improvements to gain efficiencies and enhance profitability. These companies must be prudent, because they operate on the slimmest of margins and cannot afford to invest in changes that do not offer clear ROI. The EMS industry’s adoption of technology innovations that are tagged with ‘Industry 4.0’ and ‘Smart Factory’ has been slower than many software vendors and pundits expected. What has been the barrier to adoption? Largely the origin of Industry 4.0 and related concepts were meant for the automotive industry in an attempt to use AI to replace their workforce. This has never been the vision of EMS executives and industrial engineers. Rather the promise of AI in EMS is for humans to work in tandem with AI to create more efficient manufacturing. Notably AI that can actually improve manufacturing in real-time this has been a longtime coming.

Finally in 2021, some of these innovations are finally gaining substantial traction because they solve real EMS industry problems. One such technology has recently come to our attention: PowerArena’s computer vision solution focuses on the assembly line, to provide industrial engineers with time and motion data that enables them to uncover the bottlenecks and inefficiencies that can pay off very quickly when corrected.

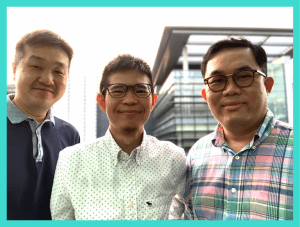

From left, Hang Wong, Ken Law, and Hauman Chow.

PowerArena’s three co-founders are deeply committed to manufacturing. Ken Law, Hauman Chow, and Hang Wong describe themselves as software engineers with friends and family in manufacturing. “We’ve felt the frustration of engineers reaching a limit to understanding the physical world. We know the feeling when intuition-based fine tuning fails to deliver improvement. We’re committed to making sure PowerArena will take human understanding of real-world engineering to new levels of efficiency,” they say.

Since its inception in 2017, PowerArena has received accolades from industry stalwarts and technology enthusiasts. Against incredible deep learning competition, PowerArena stood out at the 2019 Jumpstarter Global Pitch Competition organized by the Alibaba Entrepreneurs Fund. This gave greater exposure to the solutions PowerArena is able to deliver to EMS firms and led to their first EMS partnership. Having participated in Stanford University’s tech incubator, StartX, an original vision was to create an AI product with consumer-level user experience ease while delivering enterprise level value. Feedback from industrial engines, line managers, and executives suggests that PowerArena has delivered on this vision. That said, three of the top five EMS firms in the world are using PowerArena. Take Wistron for example, headquartered in Taipei; using PowerArena they were able to reduce a line from 17 to 16 workers while maintaining production and reducing their cost by 5.9%.

Using any CCTV camera’s video feed, PowerArena’s AI software collects and analyzes assembly line activities to be studied by industrial engineers to quickly improve processes. Using what they call ‘BYOAI’ – or build your own AI, the system can be trained by the user to observe the critical movements and objects that make up the assembly line. The ability to record assembly line workers’ movements remotely has proven especially useful during this past year where industrial engineers’ in-person access has been so limited. Using cameras in real-time has substantial advantage over sporadic time and motion sampling observations by a company’s IE team. These cameras can be moved anywhere within the manufacturing facility, ensuring the solution can be optimized for multiple uses.

One of the most useful features of the solution is the PowerArena dashboard, which can be accessed and viewed by multiple parties at the same time. Examples of applications of the data analysis include SOP assistant, line balancing, and downtime analysis. To this end, PowerArena’s AI fully supports the principles of Lean/6Sigma manufacturing. The AI enables the user to conduct root cause analysis, develop countermeasures, standardize the findings and quantify the results. PowerArena clients, which include at this point an impressive number of top tier EMS companies, report substantial ROI.

Another powerful feature is the solution’s connectivity with a client’s own Internet of Things network. This enables the AI to become more deeply integrated into the client’s entire Smart Factory ecosystem. PowerArena’s team of data scientists are available to consult with customers long after the invoice is paid to ensure maximization of the platform.

As the 21st century has shown us thus far, technological innovations in manufacturing come slow but when they arrive, they can take an industry by storm. AI worthy of top EMS firms has long been desired but a replicable product-market fit hasn’t been available until now. With an understanding of this opportunity, PowerArena has delivered usable AI meant to create a smarter factory that allows humans to discover and implement new efficiencies. Notably, the emergence of PowerArena appears to be a defining moment for the role of AI in the EMS industry as the concept of humans working together with AI has only now become a reality. Finally, with PowerArena, it appears we have an industry defining technology that gives dimension to Industry 4.0 in just the way EMS needs, with AI assisting humans.

For more information go to www.powerarena.com.