Democratizing Manufacturing

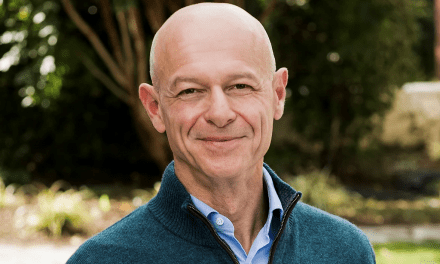

How can small businesses overcome the crippling cost of manufacturing? Mayku are making raw materials and desktop vacuum forming technology accessible for rapid and cost-effective in-house production Co-Founder and CEO of Mayku, Alex Smilansky, discusses the commitment to democratising manufacturing, with Under The Roof

For any product-based startup or small business, the cost of accessing high quality materials for their design and product development process is typically one of the most prohibitive barriers they must overcome.

The difficulty of fabrication represents one of the biggest roadblocks for a company looking to make their own products, because setting up a manufacturing facility and gathering the range of materials needed typically requires a considerable investment in raw materials and facilities.

However, companies such as Mayku are working to democratise manufacturing and empower businesses to scale, by providing them with access to industrial grade materials (and the equipment needed to utilise them) at a fraction of the cost charged by third party manufacturers. Mayku provides desktop vacuum forming technology, enabling businesses to rapidly design their products and carry out small to medium manufacturing runs in-house, far faster and cheaper than could be achieved than with traditional manufacturing processes.

Under The Roof

UTR (Under the Roof) Decorating is a Canadian toolmaking company. It develops, tests, manufactures and supplies an innovative line of home decorating products to retailers around the globe.

While UTR designs all of its products in Canada, they are manufactured in China. In the past, it had to get all of its prototypes made there as well. Sending prototypes from China to Canada was time-consuming, costly and it exposed them to potential damage in-transit, and the product development cycle was often extended as a result of delays.

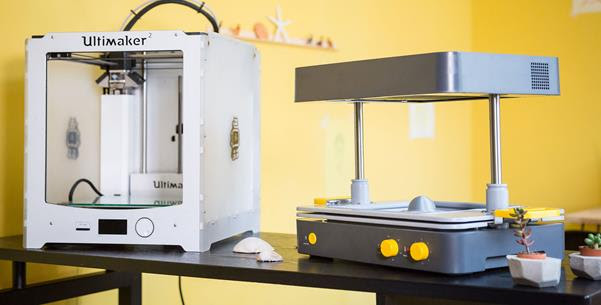

Now, UTR uses the FormBox to prototype its blister packaging designs. The entire UTR product range is blister packed with a printed card backing. Using the FormBox and transparent Mayku Cast Sheets, the team is able to replicate mass produced blister packs without leaving the in-house workshop. By producing all of its packaging in-house with a 3D printer and FormBox, there was no chance of any mistakes being made in the transition from idea to physical form. This totally eradicated the need for prototyping in China and reduced the risk of damage in-transit, shipping delays or expensive mistakes. After introducing the FormBox and 3D printing process, UTR reduced its lead time on packaging development from an average of three months to just two days, and saved an average of $1,000 per project.

Mayku’s FormBox

Mayku’s FormBox enables anyone, from a one-man band to well established businesses, to benefit from desktop-sized vacuum forming technology and the high grade materials needed for companies to design and create their own products, thereby allowing micro businesses to get their products onto shelves without necessarily building a manufacturing facility.

Mayku’s revolutionary technology, along with their closely-knit online community of designers, engineers, manufacturers and creators, support companies to continue their business activities and boost their product development efforts, across multiple industries and sectors.

Alex Smilansky, CEO and Co-Founder of Mayku, comments on Mayku’s commitment to democratising manufacturing and helping individuals and small businesses to scale their product development:

“The traditional model of manufacturing makes it so difficult for small businesses to get started, because very few third-party manufacturers and material suppliers accept small runs of products and typically provide raw materials in bulk.

This means that designers, engineers ,and business leaders across the country are ultimately prevented from following their passion and building their own businesses from the ground up, purely because the outdated model of manufacturing restricts them from accessing the tools, materials and equipment necessary to create their products.

Mayku are working to help companies tackle these issues by offering industrial-grade materials and desktop manufacturing equipment accessible to all. We provide companies with raw materials at low quantities, whilst our FormBox empowers companies to make small runs of products and being to sell immediately, without having to commit to costly large-scale manufacturing runs.

Mayku is made up of a community of passionate designers, engineers, crafters and industry experts, committed to democratising manufacturing and empowering anybody to kickstart their own businesses.”